How Are Modern Punch Presses Boosting Industrial Productivity?

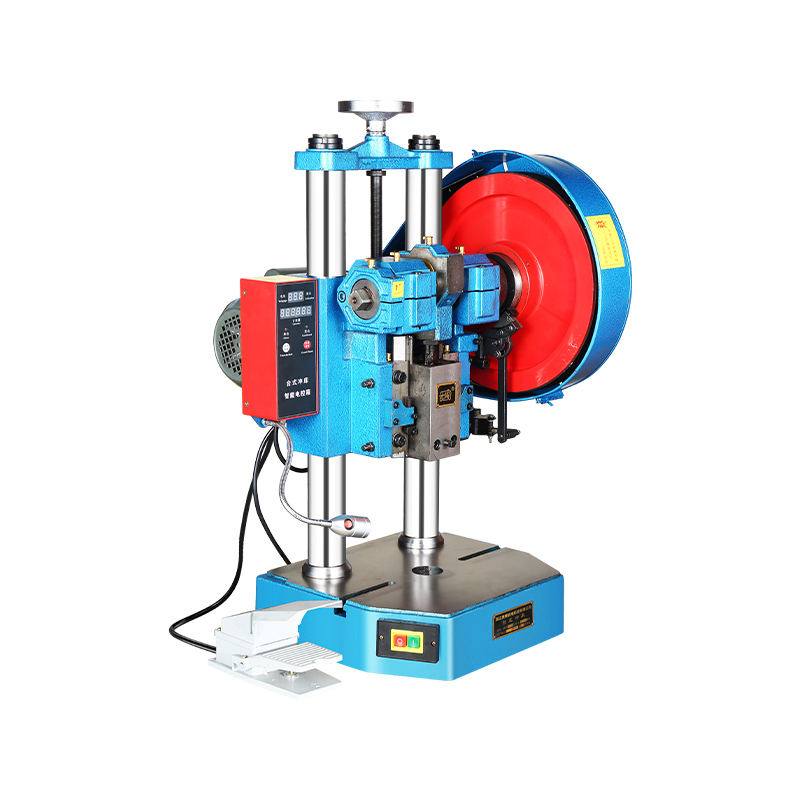

In metalworking and fabrication industries, efficiency, precision, and operator safety are becoming critical priorities. Professionals across overseas forums and industrial social media are increasingly discussing tools that streamline production without compromising accuracy. Among these innovations, the Counting Punch Press stands out for its ability to maintain consistent output while tracking operations, whereas the Foot Operated Electric Punch Press offers enhanced control and ergonomics, enabling faster workflow in diverse manufacturing settings.

Enhancing Workflow Efficiency with Counting Punch Presses

Counting punch presses are engineered to provide high-precision punching while tracking the number of operations in real time. This feature is particularly valuable in high-volume production environments, where accurate part counts are essential for inventory management, quality assurance, and workflow optimization. Manufacturers emphasize that precision engineering and reliable components are key to delivering consistent results that meet global standards.

The Advantages of Foot Operated Electric Punch Presses

Foot operated electric punch presses combine electrical power with hands-free operation, improving operator control and safety. Users on professional forums frequently highlight the benefits:

- Increased productivity due to hands-free handling

- Enhanced accuracy for repetitive punching tasks

- Reduced operator fatigue over long production runs

- Safer operation in fast-paced industrial environments

From a manufacturer’s perspective, delivering this performance requires precise calibration, robust electrical systems, and durable mechanical components to ensure consistency and longevity.

Key Factors Driving International Interest

Based on feedback from overseas buyers, several criteria consistently influence the selection of punch presses:

- Stable, repeatable punching accuracy

- Ergonomic design for operator comfort

- Long-term durability and reliable electrical components

- Compatibility with multiple sheet materials and thicknesses

These considerations indicate that buyers are prioritizing practical, performance-driven features over short-term cost savings.

Applications Across Different Industries

Counting and foot-operated punch presses are widely used in metal fabrication, automotive parts production, electrical panel manufacturing, and construction hardware workshops. Each application requires precise punching, minimal material waste, and consistent throughput. By understanding these operational demands, manufacturers can design presses that meet real-world requirements while enhancing overall productivity.

Manufacturing Expertise Behind Reliable Punch Presses

As a dedicated manufacturer, we maintain strict control over all production stages—from component sourcing and precision machining to final assembly and quality inspection. This ensures that each Counting Punch Press and Foot Operated Electric Punch Press performs reliably, even under continuous industrial use. Overseas buyers increasingly recognize the value of working with manufacturers who provide both technical expertise and consistent product quality.

Trends Highlighted by Overseas Professionals

Professional forums and social media discussions reveal several trends driving adoption:

- Preference for automation combined with manual flexibility

- Increased focus on operator safety and ergonomics

- Demand for tools that integrate easily into existing production lines

- Emphasis on quality assurance and consistent output

These trends demonstrate a growing awareness that advanced punch presses are not just tools—they are integral components of modern fabrication workflow.

Supporting Long-Term Production Success

From a manufacturer’s perspective, providing reliable Foot Operated Electric Punch Press solutions and high-precision Counting Punch Press designs is about more than selling equipment—it’s about supporting operational confidence, workflow efficiency, and product quality. By combining precision engineering, controlled manufacturing, and robust design, we help overseas clients achieve consistent performance, safety, and productivity in their workshops worldwide.

-

Feedback

English

English 中文简体

中文简体