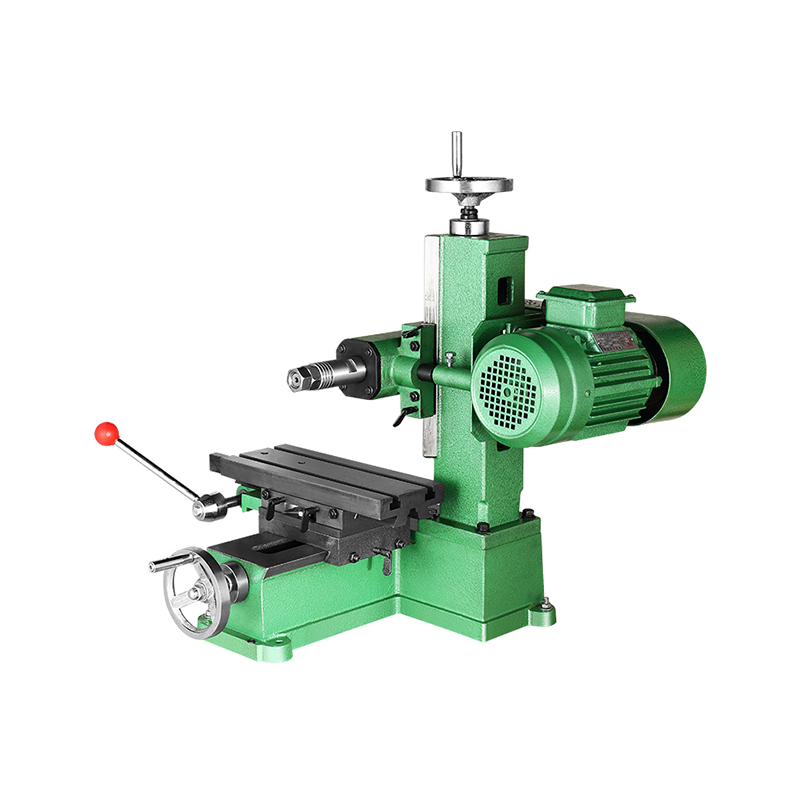

Tips for Improving Accuracy on a Desktop Mini Milling and Grinding Machine

Improve the efficiency of your Desktop Mini Milling and Grinding Machine for small-scale projects by combining skill, determination, and meticulous accuracy to achieve flawless outcomes. Regardless of whether you are a hobbyist, a beginner, or an experienced professional creating detailed parts, precision is crucial for good workmanship. Increasing the precision of your machine not only enhances the quality of your projects but also extends the life of your cutting tools.

To achieve heightened accuracy with your Desktop Mini Milling and Grinding Machine, it is crucial to ensure that your workspace and machine are both stable and secure. Position the machine on a solid, non-vibrating surface to prevent vibrations from causing erratic movements and inaccuracies during the cutting or grinding process.

Additionally, it is imperative to firmly secure the workpiece to prevent any minor shifts that could compromise the final product. Employing appropriate clamps or a vice designed for small-scale operations will help maintain the stability of your materials, thereby increasing precision.

You can accumulate dirt, dust, and debris on the moving parts of your Desktop Mini Milling and Grinding Machine, resulting in erratic movements and a decrease in accuracy. Regular maintenance, including thorough cleaning of the spindle, rails, and clamps, is essential to maintain consistent performance and precision.

Lubricate the moving parts as recommended in the machine’s manual to keep them moving smoothly. A well-maintained machine not only performs better but also has less wear, which helps maintain accuracy over time.

Choosing appropriate tools is key for precise work on a Desktop Mini Milling and Grinding Machine. Using worn or incorrect bits and grinding wheels can cause rough finishes or uneven cuts.

Make sure the cutting tools are sharp and compatible with the material you are working on. Replace dull bits promptly, as dull tools require more pressure, increasing the chance of errors.

Controlling the speed and feed rate of your Machine impacts both the finish quality and accuracy. Too high a speed or feed rate can cause chatter or vibration, reducing the precision of cuts or grinding.

Experiment with different speed settings and feed rates based on the material and task. Slower speeds often provide smoother finishes and better control, especially for delicate materials or detailed work.

Many Desktop Mini Milling and Grinding Machines have fine adjustment screws or dials to help position the tool and workpiece precisely. Take advantage of these features to make small, controlled movements rather than large, rough adjustments.

Moving the tool incrementally helps avoid overshooting your target measurements and ensures better repeatability when performing multiple cuts.

Before turning on your Desktop Mini Milling and Grinding Machine, plan your cuts or grinding carefully. Use measuring tools like calipers, rulers, or squares to mark your workpiece clearly.

Having visible guides helps you stay on track during machining and reduces the chance of mistakes caused by guesswork.

If possible, perform test cuts or grinding on scrap material before working on your final piece. This allows you to verify settings, speed, and feed rate, as well as practice your technique on the Desktop Mini Milling and Grinding Machine.

Good lighting is often overlooked but is critical when working with a Machine. Clear visibility allows you to monitor the cutting or grinding process closely and make necessary adjustments in real-time.

Consider using adjustable lamps or LED lighting to reduce shadows and highlight the working area.

Rushing through tasks on a Desktop Mini Milling and Grinding Machine can result in mistakes and reduced accuracy. Allow yourself enough time to focus on each step, make precise adjustments, and monitor the work carefully.

Patience is especially important for detailed or complex projects where every fraction of a millimeter counts.

Finally, regularly calibrate your Desktop Mini Milling and Grinding Machine according to the manufacturer’s instructions. Calibration ensures that the machine’s movements correspond correctly to the input settings, which is essential for accuracy.

Improving accuracy on your Desktop Mini Milling and Grinding Machine is a combination of proper setup, maintenance, tool choice, and careful operation. By following these tips—such as ensuring stability, using the right tools, controlling speed, and practicing patience—you can achieve higher-quality results with greater confidence.

Whether you are milling small parts or grinding delicate materials, attention to detail and good habits go a long way in getting the many out of your Desktop Mini Milling and Grinding Machine. With consistent care and practice, your precision and craftsmanship will continue to improve.

-

Feedback

English

English 中文简体

中文简体