Troubleshooting Common Issues with Your Manual Punch Press

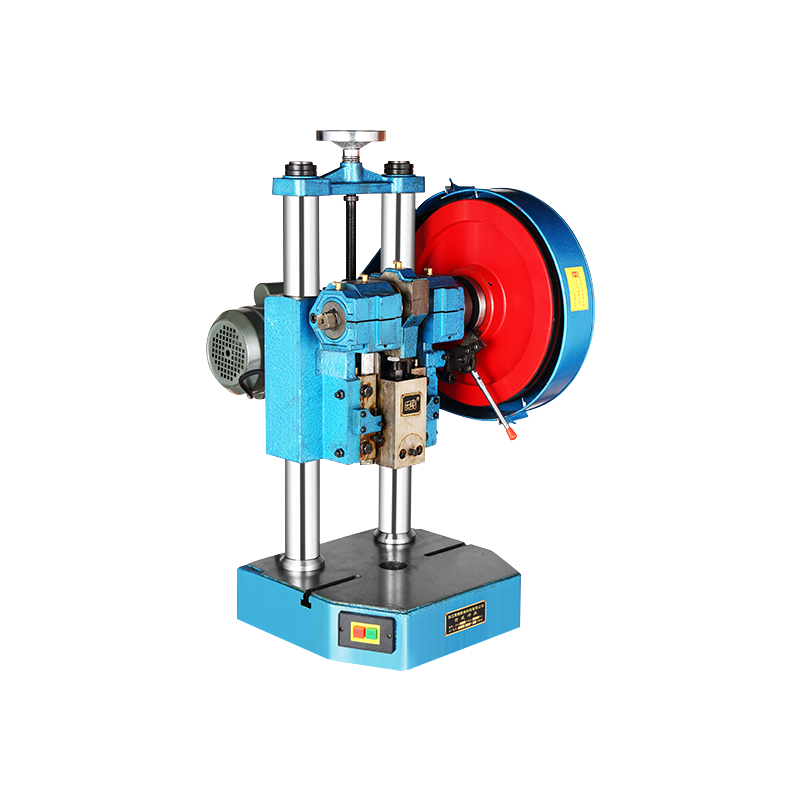

The manual punch press has long been a reliable tool in metalworking, offering control, precision, and efficiency for a variety of tasks. However, like any mechanical device, it can encounter issues from time to time. Regular maintenance and troubleshooting are necessary to keep your Custom manual punch press functioning smoothly. This article will explore some of the common issues you may face with your manual punch press and provide practical solutions to address them.

One of the common issues with a manual punch press is insufficient punching power. When the press fails to punch through the material, it can be frustrating and time-consuming. There are several reasons this could happen.

Possible Causes:

Insufficient force: The press may not be getting enough force, either due to a worn-out or improperly adjusted ram or spring.

Material issues: If the material is too thick or hard for the press to handle, it can result in inadequate punching power.

Tool wear: Worn-out dyes or punches may not generate enough impact to effectively punch the material.

Solutions:

Check the ram and springs: Ensure that the ram is properly adjusted and functioning. If the spring is worn out, replacing it should restore the press's punching power.

Use the correct tool for the material: Make sure that the punch and die are appropriate for the material you are working with. If necessary, switch to a punch with a larger diameter or use a die designed for thicker material.

Replace worn tools: Regularly inspect and replace any worn punches or dyes to maintain the OEM Industrial Punch Press's punching power.

Misalignment between the punch and die can result in uneven or inaccurate cuts, which compromises the quality of the final product. This issue can be caused by improper setup or wear over time.

Possible Causes:

Loose or worn components: Over time, the parts of the manual punch press that hold the punch and die may wear out, resulting in misalignment.

Improper setup: Incorrectly installed dies or punches can also cause misalignment.

Uneven wear: If the punch or die has worn unevenly, it can result in poor alignment, even if the press itself is properly maintained.

Solutions:

Tighten components: Check and tighten all bolts and screws that secure the punch and die. Ensuring that everything is properly aligned will help maintain accuracy.

Use alignment tools: Some manual punch presses come with alignment tools that help position the punch and die correctly. Make sure these tools are used during setup.

Replace worn parts: If the punch or die is excessively worn, replacing them can restore proper alignment and ensure clean, precise punches.

Another issue that can arise with a manual punch press is damage to the punch or die. Damaged components not only affect the performance of the press but can also result in damaged workpieces.

Possible Causes:

Overloading the press: Using excessive force or attempting to punch materials beyond the press's capacity can result in damage.

Improper material handling: Hard or abrasive materials can cause excessive wear or chipping of the punch or die.

Inadequate lubrication: Lack of lubrication can result in increased friction, causing unnecessary wear and tear on the punch and die.

Solutions:

Avoid overloading: Always ensure that the material being punched is within the specifications of the manual punch press. Overloading the press can result in not only tool damage but also mechanical failure.

Proper material selection: Be mindful of the material’s hardness. Materials that are too tough for the press can cause damage to the punch or die.

Regular lubrication: Regularly lubricate the punch and die to reduce friction and ensure smooth operation. This can help extend the life of the tools.

The Hand Held Punch Press Maker is an essential tool in many manufacturing environments, but like any machinery, it can experience issues over time. By identifying the causes of common problems, such as lack of punching power, misalignment, tool damage, uneven cutting, and excessive noise, you can keep your press operating well. Regular maintenance, proper setup, and attention to detail can help prevent many of these problems. When issues do arise, knowing how to troubleshoot and address them can ensure that your manual punch press continues to deliver reliable, high-quality results for your workshop.

-

Feedback

English

English 中文简体

中文简体