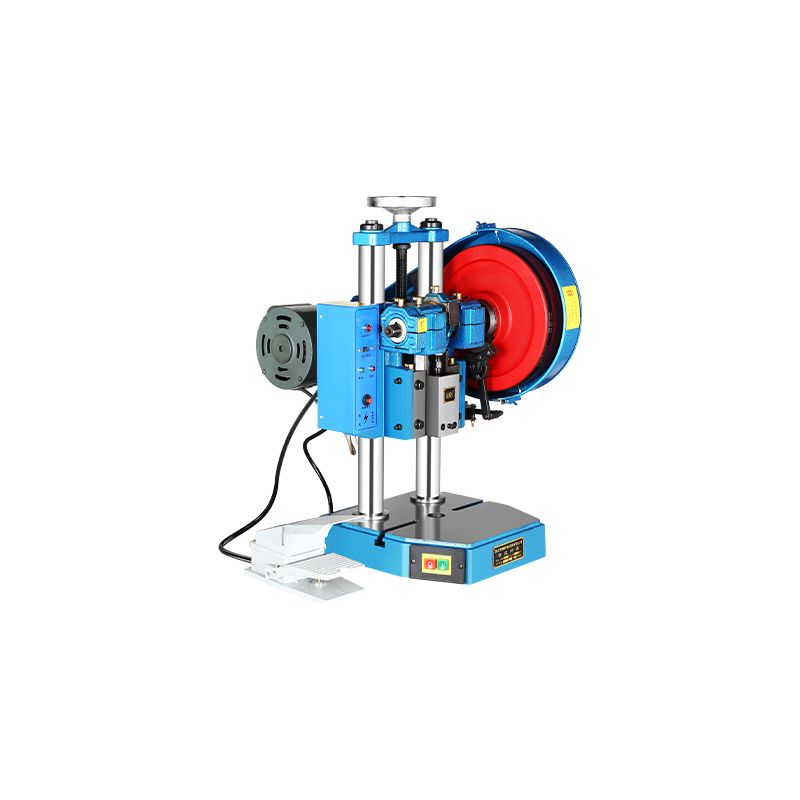

2025 Workplace Safety Shifts: Why the Two-hand Button Electric Press Is Non-Negotiable for Manufacturers

As workplace safety regulations grow increasingly stringent worldwide, manufacturers are prioritizing alignment with updated standards—especially amid a growing regulatory focus on mechanical power press safeguards. The Two-hand Button Electric Press has emerged as a pilot solution, not only for compliance but also for proactive risk reduction in industries like metal fabrication, automotive parts production, and electronics manufacturing. This tool’s design directly meets core safety requirements for concurrent two-hand operation to prevent accidental activation, making it essential for facilities that want to avoid penalties and protect workers.

What Makes It a Compliance Game-Changer?

Key workplace safety standards clearly require two-hand control systems to be designed for simultaneous operation, with safeguards against unintended use. Unlike older single-hand or foot-operated presses, the Two-hand Button Electric Press ensures both hands stay away from dangerous moving parts during operation—its buttons are spaced to prevent single-hand activation, and releasing either button immediately stops the machine. This isn’t just about meeting a rule—it’s about eliminating risks that advance to preventable injuries, such as amputations from contact with die areas. Safety managers increasingly note how such purpose-built equipment helps avoid accidents and pass inspections.

How Does It Adapt to Evolving Audits?

Today’s safety audits go beyond basic compliance to focus on proactive risk management, a trend highlighted in recent industry safety reports. Many Two-hand Button Electric Press models integrate with safety management software, allowing facilities to record operation data and demonstrate compliance effortlessly. Safety experts consistently seek tools that simplify audit preparation, and this press delivers by making safety practices measurable and easy to document—critical for navigating modern, data-driven inspection processes.

Beyond Compliance: The Productivity Surprise

Some manufacturers worry that safety tools might slow production, but real-world use tells a different story. Users of the Two-hand Button Electric Press report its anti-repeat feature—required under safety regulations for certain machinery—reduces mistakes and rework, actually boosting efficiency. This feature prevents unintended repeat strokes without full button release, eliminating errors that waste materials and time. The blend of safety and speed has made the press a topic of positive discussion in industry forums.

Enhanced Protection for Diverse Applications

The Two-hand Button Electric Press is engineered for versatility across industries, delivering consistent safety performance in metal stamping, plastic molding, and assembly operations alike. Its adjustable settings accommodate different materials and thicknesses, while its safety distance design—calibrated to ensure hands can’t reach hazard zones before the machine stops—works for both short-run job shops and high-volume production. This adaptability makes it a fit for diverse modern manufacturing needs.

Reducing Long-Term Costs

While the initial investment may exceed that of traditional presses, the long-term savings are substantial. Fewer accidents translate to lower insurance premiums and less unplanned downtime. Its electric operation cuts energy use compared to hydraulic systems, slashing utility bills. Additionally, the press’s durable construction—using robust materials that resist wear from industrial use—means less maintenance and a longer lifespan, minimizing replacement costs over time.

Supporting Workforce Confidence and Skills

Workers perform better when they feel secure, and the Two-hand Button Electric Press fosters this confidence through intuitive, safety-focused design. Clear operation feedback and enforced proper technique help build strong work habits, while visible safety features (like protected buttons and stop controls) simplify training for new employees. This not only strengthens safety culture but also boosts job satisfaction and retention—critical for maintaining a skilled workforce.

The Two-hand Button Electric Press is no longer an optional luxury but a necessary investment for modern manufacturers. It meets evolving safety regulatory demands while enhancing productivity and protecting workers. As safety standards continue to tighten, using equipment aligned with core compliance standards will be crucial for any manufacturer committed to both regulatory adherence and operational excellence.

-

Feedback

English

English 中文简体

中文简体