How Are Smart Press Solutions Shaping the Next Stage of Factory Upgrades?

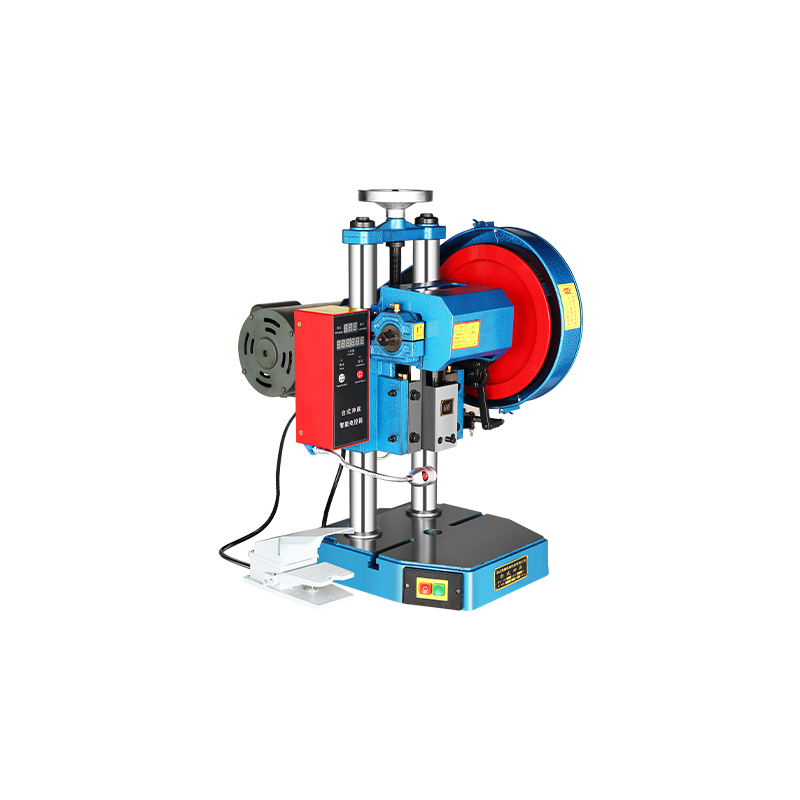

Across global manufacturing communities, a clear message is emerging: factory upgrades are no longer driven only by speed or scale. Instead, overseas buyers are actively discussing how smarter press solutions can improve control, safety, and long-term operational stability. In this environment, the Counting Punch Press has gained attention for enhancing production awareness, while the Two-hand Button Electric Press is increasingly viewed as a practical safeguard for daily operations. Together, they represent a new direction in press equipment selection.

From Output Volume to Process Confidence

In many international markets, manufacturers are shifting their focus from sheer output volume to process confidence. Buyers want to understand not only how fast a press operates, but how reliably it performs across multiple shifts and product batches.

Counting punch press systems support this shift by making production flow more visible. Operators can better understand progress without constant manual checks, while supervisors gain clearer insight into daily workloads. This transparency is especially appealing to overseas factories managing small-batch or mixed production, where accuracy matters as much as speed.

Why Human-Centered Safety Is a Global Topic

Workplace safety has become a recurring theme on overseas social platforms and industry forums. Beyond regulatory compliance, manufacturers are concerned about protecting skilled workers and maintaining stable teams.

The two-hand button electric press aligns well with this mindset. Its operation logic naturally encourages safe engagement, reducing the likelihood of accidental activation. Many buyers see this design as a practical way to enhance safety culture without disrupting existing workflows or requiring extensive retraining.

Supporting Lean Manufacturing Goals

Lean manufacturing principles continue to influence equipment purchasing decisions worldwide. Reducing waste, avoiding rework, and maintaining consistent cycles are central goals for modern workshops.

Counting punch presses contribute by helping prevent overproduction and miscounts, which can advance to material waste. Meanwhile, two-hand button electric presses promote controlled, deliberate operation, minimizing errors caused by rushed handling. Together, these features support lean practices that overseas buyers are actively pursuing.

Adapting to Workforce Changes

Another topic gaining traction internationally is workforce change. With experienced operators retiring and younger workers entering the industry, factories need machines that are easier to understand and operate.

Counting punch press solutions reduce reliance on manual tracking, making production goals clearer for less experienced staff. Two-hand button electric presses offer intuitive controls that help new operators feel confident more quickly. This adaptability is frequently mentioned by buyers looking to stabilize production amid labor shifts.

Versatility for Multi-Industry Applications

Overseas manufacturers often serve multiple industries, from automotive components to general hardware. This diversity requires press equipment that can adapt to different tasks without complex reconfiguration.

Counting punch presses are valued for their flexibility across various punching operations. Two-hand button electric presses complement this by providing consistent performance in different application scenarios. Their broad usability helps factories respond to changing customer demands, a key concern discussed in global sourcing communities.

Enhancing Daily Operational Discipline

Consistency is another recurring keyword in international buyer discussions. Machines that encourage disciplined operation help reduce variability between shifts and operators.

The structured counting function of a counting punch press promotes better adherence to production plans. At the same time, the deliberate activation process of a two-hand button electric press reinforces careful handling. This combination supports a more disciplined shop floor environment, which overseas buyers often associate with higher overall quality.

Building Long-Term Equipment Value

Beyond initial purchase considerations, global buyers are increasingly evaluating total ownership value. Equipment that supports stable operation and predictable maintenance is favored over solutions that offer short-term gains but long-term uncertainty.

Electric press designs are often appreciated for their controlled performance and operational stability. Counting punch presses help avoid unnecessary strain caused by overuse, while two-hand button electric presses reduce the risk of misuse. These characteristics contribute to longer service life and steadier production planning.

Aligning with Global Buyer Expectations

In today’s competitive supply chains, overseas buyers look for suppliers who understand evolving manufacturing priorities. Offering press solutions that balance efficiency, safety, and usability demonstrates a forward-thinking approach.

By combining the operational clarity of a Counting Punch Press with the safety-focused design of a Two-hand Button Electric Press, manufacturers can meet modern expectations while preparing for future production challenges. This balanced approach is increasingly recognized as a smart investment for factories seeking sustainable growth.

-

Feedback

English

English 中文简体

中文简体