Are Precision and Safety Redefining the Future of Press Machinery?

In recent overseas manufacturing discussions, precision control and workplace safety are no longer treated as optional upgrades—they are becoming baseline expectations. As factories adapt to stricter compliance standards and more diversified orders, equipment choices are evolving accordingly. Within this context, the Counting Punch Press is often mentioned for its role in improving production traceability, while the Two-hand Button Electric Press continues to attract attention as a practical solution for safer human-machine interaction. Together, these products reflect how press machinery is aligning with modern manufacturing priorities.

A Shift Toward Measurable Production Processes

One of the lots of talked-about trends across international industrial forums is the move from experience-based operation to measurable, trackable processes. Buyers increasingly want visibility into how many parts are produced, how consistent cycles are maintained, and where inefficiencies may occur.

Counting punch press solutions respond directly to this demand by enabling clearer production oversight. By helping operators and managers monitor output more intuitively, these systems support better planning and reduce uncertainty in daily operations. This capability resonates strongly with overseas buyers who are focused on transparency and lean manufacturing practices.

Why Safety-Centered Design Is Gaining More Attention

Global conversations around manufacturing safety have expanded beyond compliance to include worker retention and morale. Equipment that actively supports safe operation is now seen as an investment in workforce stability.

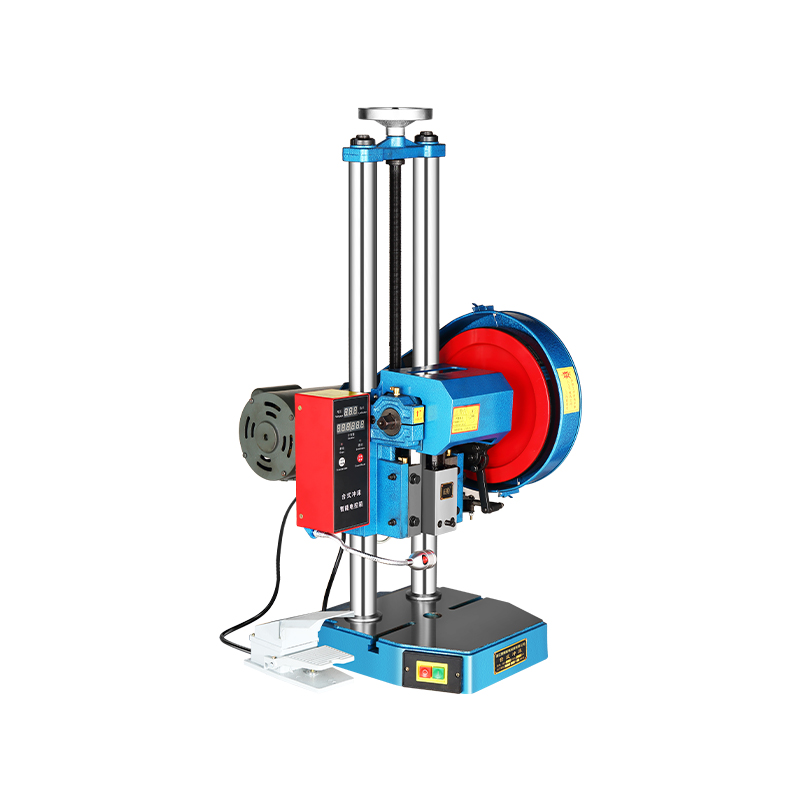

The two-hand button electric press fits naturally into this discussion. Its design encourages proper hand placement and conscious operation, helping reduce the likelihood of accidental engagement. Many buyers appreciate that this approach enhances safety without adding complexity, making it suitable for both experienced operators and new staff.

Balancing Automation and Human Control

While full automation remains a long-term goal for some factories, many overseas manufacturers are choosing a balanced path. They seek equipment that improves consistency while preserving operator control and flexibility.

Counting punch presses offer this balance by supporting repetitive tasks without eliminating human oversight. Two-hand button electric presses complement this by maintaining a clear and deliberate activation process. This combination is often highlighted as an ideal middle ground for workshops that need efficiency without the rigidity of fully automated systems.

Supporting Diverse Industry Applications

Another frequently discussed topic on social media and trade platforms is equipment versatility. Manufacturers serving multiple industries require machines that adapt easily to different materials and product types.

Counting punch presses are commonly valued for their suitability across a wide range of punching and forming tasks. Two-hand button electric presses, with their straightforward operation and stable performance, are equally adaptable. This versatility helps manufacturers respond quickly to changing order requirements, a key advantage in today’s dynamic global markets.

Reducing Training Pressure on Modern Factories

Labor challenges continue to shape purchasing decisions worldwide. With higher turnover rates and fewer skilled operators available, factories are prioritizing equipment that shortens training cycles.

Counting punch press systems simplify output management, making it easier for new operators to understand production goals. Two-hand button electric presses feature intuitive controls that reduce the learning curve. Together, they support faster onboarding and more consistent results, which is a major concern for international buyers.

Long-Term Operational Confidence

Beyond daily production, overseas buyers are increasingly focused on long-term operational confidence. Equipment reliability, ease of maintenance, and predictable performance all contribute to this mindset.

Electric press solutions are often favored for their stable operation and controlled force application. Counting punch presses help prevent overproduction and material waste, while two-hand button electric presses reduce the risk of misuse. These factors contribute to smoother operations and more confident long-term planning.

Strengthening Supplier–Buyer Relationships

In competitive global supply chains, buyers look for partners who understand evolving industry needs. Offering equipment that addresses both efficiency and safety demonstrates a forward-looking approach.

Suppliers that provide counting punch press solutions alongside two-hand button electric press options show their ability to support different production philosophies and workshop sizes. This flexibility helps build trust and encourages long-term collaboration with overseas customers.

Smarter Press Solutions

As manufacturing continues to modernize, press equipment will play a crucial role in bridging traditional craftsmanship and structured production systems. Rather than focusing solely on output speed, buyers are prioritizing reliability, clarity, and operator protection.

By integrating the production awareness offered by a Counting Punch Press with the safety-focused design of a Two-hand Button Electric Press, manufacturers can create press operations that are well-suited to current global expectations and future industry growth.

-

Feedback

English

English 中文简体

中文简体