Why Are Manufacturers Upgrading to Smarter Press Equipment Faster Than Ever?

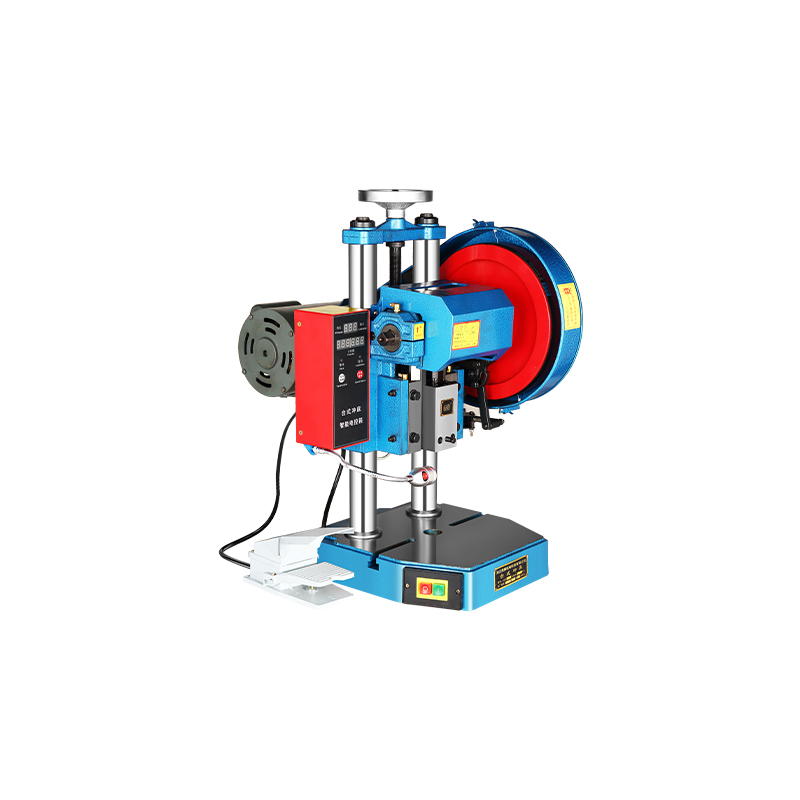

Across global manufacturing communities, conversations are shifting from simple output goals to smarter, safer, and more traceable production methods. As labor structures change and quality expectations rise, equipment selection has become a strategic decision rather than a basic purchase. In this environment, the Counting Punch Press is frequently highlighted for its contribution to production transparency, while the Two-hand Button Electric Press continues to gain attention for helping workshops improve operational safety without sacrificing efficiency. These solutions reflect a broader transformation happening on factory floors worldwide.

From Manual Operations to Structured Workflows

Many overseas manufacturers are reassessing traditional press operations that rely heavily on operator experience. While manual methods offer flexibility, they also introduce inconsistency. Counting punch press systems help bridge this gap by providing structured workflows that support repeatable operations.

Industry discussions emphasize that counting functions are particularly valuable for batch production, where consistent output tracking reduces rework and supports better inventory planning. This shift toward structured workflows aligns with global efforts to improve production accountability.

Operator Safety as a Core Productivity Factor

Safety is no longer viewed as separate from productivity. In fact, international forums increasingly link safer equipment with higher operational efficiency. The two-hand button electric press plays a key role in this conversation by encouraging correct operator positioning during press activation.

By minimizing the risk of accidental engagement, this design helps maintain steady production rhythms and reduces unplanned interruptions caused by safety incidents. For many buyers, this balance between protection and usability has become a decisive purchasing factor.

Supporting Quality Consistency in Pressing Tasks

Quality control remains a major topic in overseas manufacturing discussions, especially for industries producing standardized components. Counting punch presses allow operators to maintain consistent pressing cycles, which supports uniform product quality across batches.Meanwhile, two-hand button electric presses provide stable force control and predictable operation, helping reduce variations caused by improper handling. Together, these solutions support a more controlled production environment that aligns with global quality expectations.

Flexibility for Diverse Production Scenarios

Unlike fully automated systems that may require complex integration, these press solutions are valued for their adaptability. Counting punch presses are suitable for repetitive tasks as well as short production runs, while two-hand button electric presses are often praised for their ease of setup and operation.

This flexibility is particularly attractive to small and medium-sized manufacturers who need equipment capable of supporting multiple applications without frequent downtime or complicated adjustments.

Responding to Labor Market Changes

Another trending topic across overseas social platforms is workforce availability and training. As skilled labor becomes harder to secure, manufacturers are seeking equipment that reduces reliance on advanced operator expertise.

Counting punch presses help simplify task management by providing clear production indicators, while two-hand button electric presses offer intuitive controls that are easy to learn. This combination supports faster onboarding and more stable workforce performance.

Long-Term Value Beyond Initial Investment

International buyers increasingly evaluate equipment based on long-term value rather than upfront cost. Electric press solutions are often favored for their stable operation, predictable maintenance needs, and compatibility with evolving production requirements.Counting punch presses help reduce material waste through better output control, while two-hand button electric presses contribute to longer equipment lifespan by promoting proper use and reducing accidental damage.

Building Trust Through Reliable Equipment Solutions

In global markets, supplier reliability is just as important as product capability. Manufacturers that can provide consistent press performance, customization options, and dependable technical support stand out in competitive procurement environments.By offering both Counting Punch Press systems and Two-hand Button Electric Press solutions, suppliers demonstrate an understanding of modern production challenges—balancing safety, efficiency, and operational clarity in a single equipment lineup.

The Future of Press Operations

As manufacturing continues to evolve, the demand for equipment that supports smarter decision-making and safer workplaces will only increase. Rather than replacing human operators, modern press solutions aim to enhance their effectiveness and protection. By integrating production visibility through a Counting Punch Press and operator-focused safety via a Two-hand Button Electric Press, manufacturers can move toward more sustainable, efficient, and globally competitive operations.

-

Feedback

English

English 中文简体

中文简体