Are Smart Press Solutions Redefining Efficiency and Safety in Modern Workshops?

As global manufacturing continues to evolve toward higher productivity and safer operations, overseas buyers are paying closer attention to equipment that balances efficiency, accuracy, and operator protection. In this context, the Counting Punch Press has become a popular topic in industrial forums for its ability to support controlled production and workflow visibility. At the same time, the Two-hand Button Electric Press is frequently discussed on social media for its role in improving workplace safety while maintaining stable performance. Together, these press solutions reflect what modern workshops are truly looking for today.

Rising Demand for Controlled and Measurable Production

Manufacturers across automotive components, electronics, hardware, and light metal fabrication increasingly focus on production consistency rather than output alone. Counting punch press systems help operators and managers track production cycles more clearly, reducing errors caused by overproduction or missed counts. Overseas discussions highlight how built-in counting functions support better process control, especially for repetitive stamping tasks and standardized parts manufacturing.

This focus on measurable output aligns well with current trends in lean manufacturing and transparent production management.

Safety Awareness Driving Equipment Selection

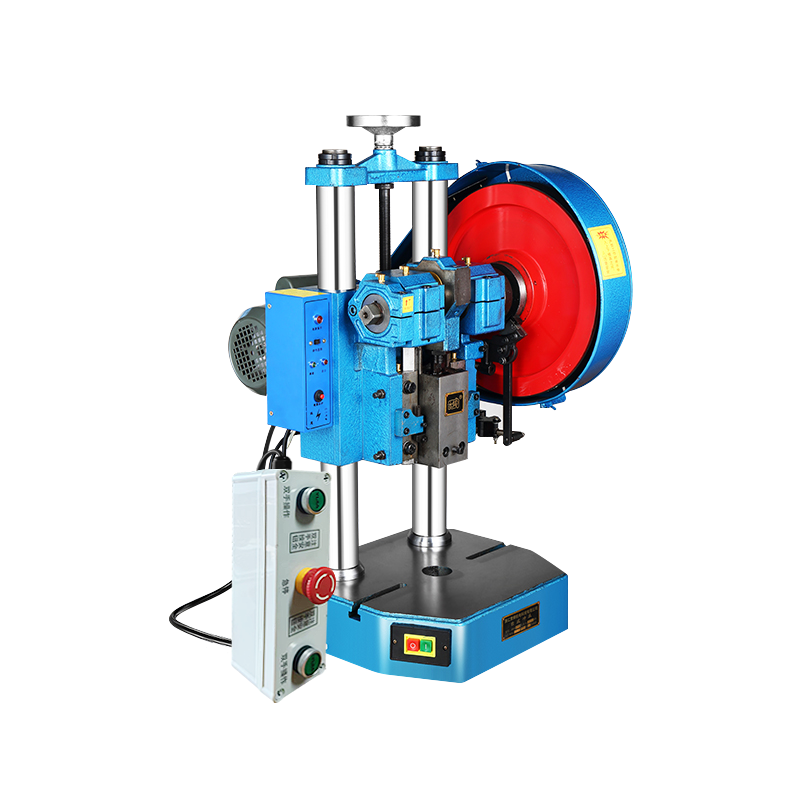

Workplace safety remains a major concern in global manufacturing communities. The two-hand button electric press is often recommended in discussions related to operator protection and compliance with safety practices. Requiring both hands to engage the press significantly reduces accidental activation, which is especially important in high-frequency operations.

International buyers increasingly view safety-oriented designs not as optional features, but as essential requirements when selecting press equipment for long-term use.

Balancing Automation and Operator Control

While full automation continues to grow, many workshops still rely on semi-automatic or operator-assisted machines for flexibility. Counting punch presses offer a balance between automation and manual control, allowing operators to manage production pace while benefiting from built-in monitoring functions.

Similarly, two-hand button electric presses provide intuitive operation without complex programming, making them suitable for facilities with varied skill levels or frequent product changes.

Applications Across Diverse Industries

Both press solutions are widely used in stamping, forming, riveting, and assembly processes. Industries such as electrical components, metal hardware, kitchenware, and appliance manufacturing benefit from accurate pressing and consistent force control.

Overseas buyers often mention that the versatility of these machines allows them to adapt to different molds, materials, and production volumes, making them suitable for both small workshops and medium-scale manufacturing lines.

Energy Efficiency and Maintenance Considerations

Another recurring topic in overseas discussions is operating cost. Electric press solutions are favored for their stable energy consumption and relatively low maintenance requirements. Compared to more complex systems, counting punch presses and two-hand button electric presses are easier to maintain, helping reduce downtime and operational disruptions.

This practicality is particularly appealing to buyers looking for reliable equipment that supports steady production without unnecessary complexity.

Choosing a Reliable Manufacturing Partner

Beyond machine specifications, international buyers focus on supplier credibility, customization capability, and after-sales support. Manufacturers that offer flexible configurations, clear technical guidance, and responsive communication are more likely to build lasting partnerships.

Providing both Counting Punch Press solutions and Two-hand Button Electric Press systems allows suppliers to meet diverse production needs while addressing safety, efficiency, and reliability—key priorities in today’s global manufacturing environment.

Looking Ahead: Smarter and Safer Press Operations

As workshops continue to modernize, the demand for press equipment that integrates monitoring, safety, and ease of use will keep growing. Rather than pursuing bad automation, many buyers seek balanced solutions that enhance productivity while protecting operators and maintaining control.

By combining the production visibility of a Counting Punch Press with the safety-focused design of a Two-hand Button Electric Press, manufacturers can offer practical, trustworthy solutions that align with current overseas market expectations and support long-term operational success.

-

Feedback

English

English 中文简体

中文简体