Is Safety Automation Reshaping the Future of Small Workshops? The Rising Demand for Electric Press Solutions!

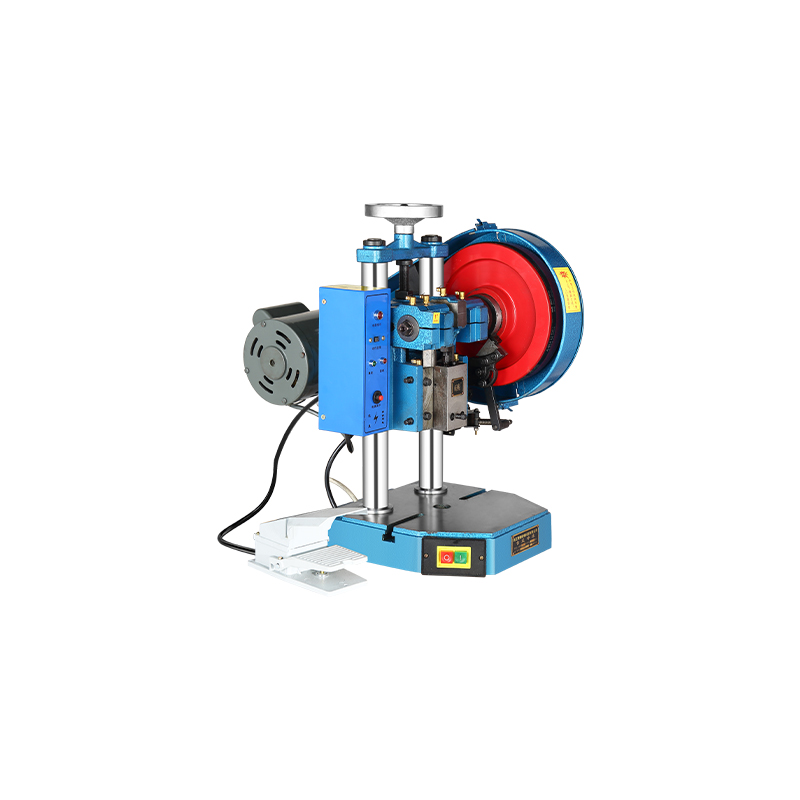

Across global manufacturing communities—especially on overseas social platforms—discussions around workplace safety, operator comfort, and efficient small-scale production are becoming increasingly active. Many workshop owners, DIY fabricators, and light-industrial manufacturers are asking the same question: How can they enhance safety without sacrificing productivity? This concern explains why devices such as the Foot Operated Electric Punch Press and the Two-hand Button Electric Press are gaining notable attention in recent months, positioning themselves as essential tools for modern, safety-first workflows.

Growing Emphasis on Safer Punching and Forming Operations

Safety has become one of the lots of talked-about themes in global manufacturing. Videos shared on industrial YouTube channels and professional Reddit groups often highlight accidents caused by manual presses and outdated machinery. This heightened awareness has created strong interest in systems that physically separate the operator’s hands from moving components.

Electric presses built with dual-control interfaces or pedal-activation mechanisms meet these expectations perfectly. They offer controlled operation while preventing accidental activation, making them valuable for workshops wanting to modernize without completely restructuring their setup.

Why Small Workshops Are Turning Toward Automation

Small and mid-size workshops increasingly seek partial automation rather than full-scale robotic systems. They want:

Consistent punching quality

Reduced operator fatigue

Easier integration with existing tools

Improved safety without complicated training

Electric press equipment fits this trend. Many overseas users on professional forums emphasize that automated activation—whether by pedal or double-hand switch—can significantly streamline repetitive tasks while maintaining the precision needed for metal components, leather goods, electronic enclosures, or custom fabrication.

Ergonomics: The New Competitive Advantage

Manufacturing discussions increasingly include ergonomics as a crucial factor in equipment selection. Workers now expect tools that reduce strain and provide a natural workflow.

What global users want today:

Standing operation options

Ability to keep hands free for material positioning

Less vibration and smoother pressing control

Reduced body pressure during long work sessions

This is where foot-operated systems and dual-button setups become extremely appealing. Operators can position materials more comfortably, maintain proper alignment, and work longer with far less strain—all points that appear frequently in online feedback from fabricators and workshop owners.

The Push for More Precise, Controlled Pressing Performance

Precision is no longer reserved for big factories. Small businesses producing custom components or boutique products rely on accurate punching and forming. Many overseas engineers mention that electric-actuated systems provide smoother, more predictable force application compared to older mechanical devices.

This rise in the demand for better accuracy aligns perfectly with the benefits of advanced electric press machines, which deliver stable performance suitable for metals, plastics, coated materials, and many semi-rigid components used across multiple industries.

Growing Environmental Awareness Encouraging the Switch

Eco-conscious manufacturing trends—often highlighted on global business forums—are pushing companies toward electric-driven tools that consume less energy and require minimal maintenance chemical use. Electric presses fit this environmentally aware direction by offering quiet operation, reduced lubrication needs, and higher efficiency.

As more regions introduce stronger workplace and energy regulations, businesses are actively searching for equipment that helps them stay compliant while improving daily workflow.

Why These Electric Press Systems Will Continue to Gain Traction

With workplace safety laws evolving and operators demanding upgraded tools, the market is clearly shifting. Workshops want machines that minimize risk, enhance comfort, and produce consistent outputs. These expectations indicate that equipment such as the Foot Operated Electric Punch Press and the Two-hand Button Electric Press will continue gaining attention among global buyers, making them strong contenders for facilities seeking a safer and more modern production environment.

-

Feedback

English

English 中文简体

中文简体