How Are Foot-Operated Electric Punch Presses Shaping the Smart Factory Era?

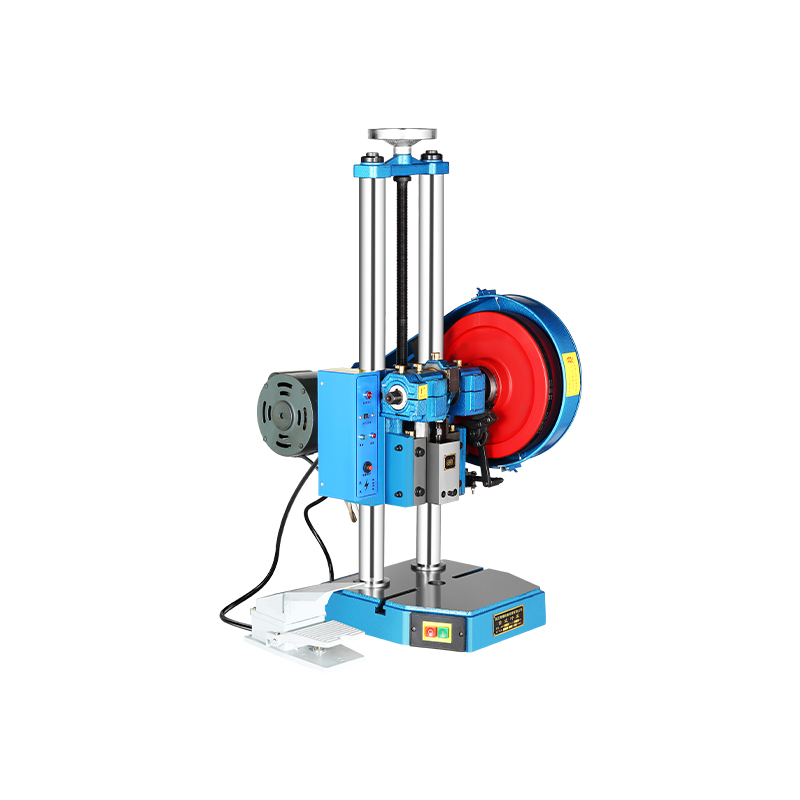

In today’s industrial landscape, factories are increasingly adopting advanced tools to improve efficiency, safety, and quality. The Foot Operated Electric Punch Press is emerging as a pivotal piece of equipment in this transformation. By enabling hands-free operation, consistent performance, and flexible integration with modern production workflows, these presses are capturing the attention of manufacturers around the globe. Industry blogs, LinkedIn discussions, and trade show demonstrations have highlighted how this technology supports smart factory initiatives, helping companies achieve higher output without compromising safety or precision.

Boosting Productivity Through Hands-Free Control

Foot-operated presses allow operators to focus on accurate material positioning while activating the press with their feet. This hands-free approach reduces handling errors and accelerates production cycles. Workshops report that operators can work more efficiently with less fatigue, especially when performing repetitive punching tasks. Global manufacturing forums show that hands-free operation is now considered a standard feature in modern press selection, reflecting a shift toward ergonomically optimized machinery.

Precision That Supports Modern Manufacturing Standards

Consistency and accuracy are vital in today’s industrial environment. Electric punch presses maintain uniform pressure and stroke length, ensuring high-quality results across every part. Industries like automotive, electronics, and HVAC rely on this repeatability to meet tight tolerances. Online technical communities increasingly discuss how foot-operated models help prevent material deformation and ensure reliable joint quality, making them a critical choice for manufacturers emphasizing quality assurance.

Enhancing Safety and Reducing Workplace Risks

Safety continues to be a primary concern in production facilities. Foot-operated electric presses keep operators’ hands away from moving punch heads, significantly lowering the risk of injury. Additional safety features such as adjustable guards, emergency stop buttons, and overload protection further protect operators. Industry safety forums and LinkedIn discussions emphasize that investing in ergonomically designed presses contributes not only to compliance but also to improved employee morale and productivity.

Adaptable and Versatile for Various Production Needs

Modern workshops often handle diverse materials and project types. Foot-operated electric presses can accommodate different die sizes, metal thicknesses, and production volumes, providing versatility that single-function machines cannot match. Social media posts and video demonstrations frequently showcase how a single press can efficiently switch between prototype work and full-scale production, making it an attractive option for both SMEs and larger factories seeking cost-effective, multi-purpose solutions.

Efficiency and Cost Reduction

By combining hands-free control, precision, and safety, foot-operated presses contribute to faster cycle times and fewer defective parts, directly reducing operational costs. Manufacturers report that integrating these tools into existing workflows minimizes scrap material and increases overall line efficiency. International buyers also note that improved productivity and reduced labor strain make these presses an essential investment for modern industrial operations.

Integration with Smart Production Systems

As factories move toward smart, connected production, the Two-hand Button Electric Press complements foot-operated models by offering enhanced safety interlocks and programmable functions. Together, these tools create a flexible, efficient, and reliable production environment, supporting automation initiatives while maintaining operator engagement. This synergy positions manufacturers to stay competitive in an increasingly technology-driven industrial landscape.

-

Feedback

English

English 中文简体

中文简体