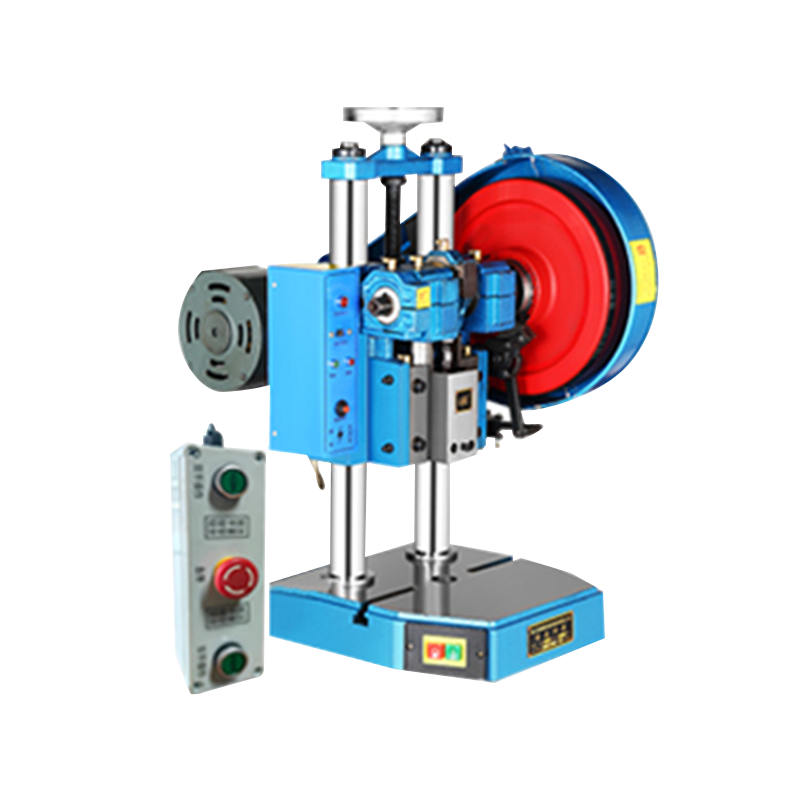

Is the Foot-Operated Electric Punch Press Driving the Next Wave of Industrial Automation?

In modern manufacturing, efficiency, precision, and operator safety are more critical than ever. The Foot Operated Electric Punch Press is becoming a central tool for workshops seeking to streamline production while minimizing manual labor strain. By combining hands-free operation with consistent performance, these presses are attracting attention from factories worldwide. Online engineering communities and industry trade forums increasingly highlight their role in supporting automated workflows, faster cycle times, and improved quality control, making them an essential part of modern production strategies.

Hands-Free Design Enhances Workflow Efficiency

One of the lots of compelling advantages of foot-operated presses is the ability to keep both hands free while performing punching tasks. This design enables operators to precisely position materials, reducing errors and increasing speed. In environments where hundreds of punches are executed daily, this hands-free approach not only saves time but also allows employees to maintain higher productivity throughout long shifts. Many workshops report smoother workflow integration and fewer interruptions when switching between different workpieces.

Consistency and Accuracy Across Operations

Precision remains a key factor in industrial manufacturing. Electric punch presses are designed to deliver repeatable strokes with uniform force, ensuring that every part meets stringent quality standards. Industries such as automotive, electronics, and HVAC rely heavily on this level of accuracy. Case studies shared in online forums and technical webinars consistently emphasize how foot-operated presses reduce the risk of misalignment, uneven cuts, or defective parts, providing manufacturers with confidence in their production outputs.

Safety Improvements for Modern Operators

Safety continues to be a top priority in factories worldwide. Foot-operated presses minimize the risk of injury by keeping operators’ hands away from moving punch heads. Many models include safety features like adjustable guards, emergency stops, and overload protection, which further enhance workplace safety. Discussions on LinkedIn and Reddit reveal that manufacturers increasingly value tools that protect workers without compromising speed or efficiency, reflecting a strong trend toward ergonomic and safe industrial equipment.

Adaptability to Various Materials and Jobs

From thin sheet metals to thicker composites, modern foot-operated electric presses handle a wide range of materials and die sizes. This versatility allows manufacturers to switch between tasks without investing in multiple machines. Social media platforms and trade discussions frequently highlight the ability to perform multiple functions on a single press, from prototype work to high-volume production, making these presses appealing to both small workshops and large factories.

Cost and Time Savings Through Efficiency

Faster cycle times, reduced error rates, and minimized material waste contribute to operational cost savings. Foot-operated electric presses help businesses optimize labor allocation while improving output quality. Many international buyers note that these tools can provide measurable ROI by increasing productivity, lowering scrap rates, and supporting lean manufacturing practices. The efficiency gains are often amplified when used alongside complementary machinery, creating a more streamlined production process.

Integration With Digital and Automated Systems

The future of industrial punching involves smarter, more integrated tools. Combining a Two-hand Button Electric Press with a foot-operated model allows manufacturers to balance manual control with automation, increasing production reliability and flexibility. These tools can work in tandem with digital monitoring, programmable cycles, and safety interlocks, enabling modern workshops to meet both production goals and evolving regulatory standards. By adopting these presses, factories are positioning themselves at the forefront of industrial efficiency and innovation.

-

Feedback

English

English 中文简体

中文简体