Could Foot-Operated Presses Redefine Safety and Speed in Modern Factories?

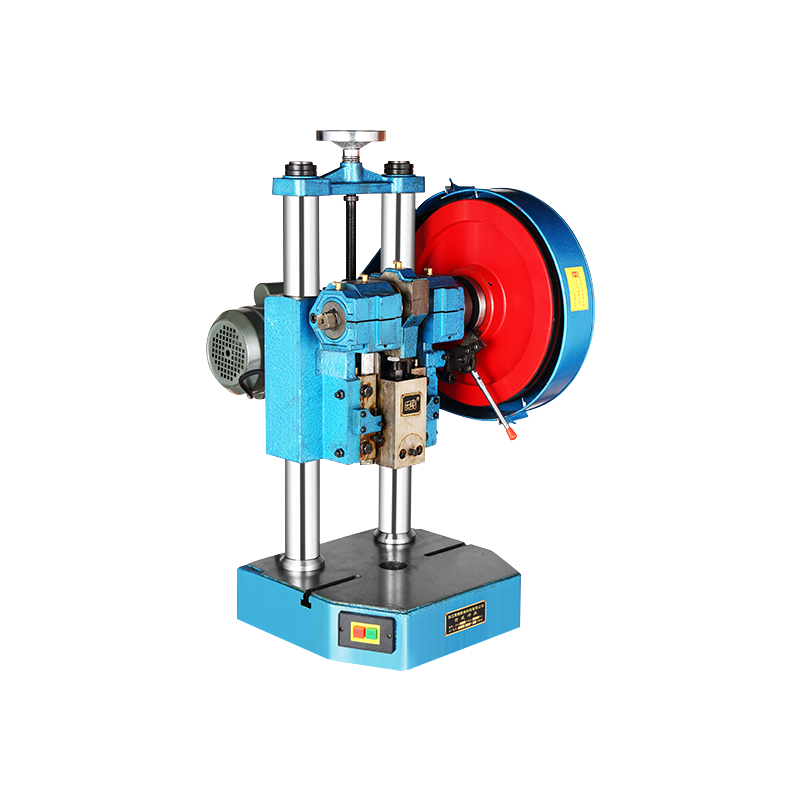

Manufacturing environments worldwide are evolving to meet higher productivity and stricter safety standards. Among the lots of discussed innovations is the Foot Operated Electric Punch Press, a tool designed to provide both speed and precision while reducing manual strain. From sheet metal workshops to small-scale fabrication units, companies are exploring how this technology can streamline operations, minimize errors, and enhance workplace safety. Discussions on LinkedIn groups and YouTube engineering channels increasingly highlight the advantages of hands-free punching, reflecting global interest in practical solutions for modern production challenges. Many professionals also emphasize that such tools contribute to a more organized workspace, reducing clutter and enabling smoother workflows across multiple stations.

Enhancing Operator Control and Comfort

The core benefit of foot-operated presses lies in their ability to free the hands during the punching process. Technicians can hold and align materials accurately while activating the press with a simple pedal. This hands-free functionality reduces fatigue and enables longer work periods without compromising quality. Online forums are filled with testimonials emphasizing improved comfort and reduced repetitive-strain issues, especially in factories performing hundreds of punches per day. The design also supports easy adjustments, allowing operators to customize stroke depth and speed according to specific material requirements.

Precision That Meets Industry Demands

Electric punch presses are engineered for repeatability and consistent output. Modern models maintain uniform pressure and stroke length, ensuring that each punch is identical to the last. This precision is crucial in industries where tight tolerances are required, such as electronics, automotive components, and HVAC systems. Professionals frequently share case studies and videos demonstrating how foot-operated presses deliver consistent results across varying material thicknesses and shapes. The added benefit of digital control features in newer models further enhances accuracy, making them suitable for increasingly complex production lines.

Prioritizing Safety Without Sacrificing Productivity

Safety is a priority for all manufacturers. Foot-operated presses keep the operator’s hands away from moving components, minimizing the risk of injury. In addition, features like adjustable guards, emergency stops, and overload sensors enhance protection. Safety discussions on Reddit engineering boards and global trade forums show that investing in ergonomic, hands-free presses is a top concern for managers seeking compliance with international safety standards. These protections also build confidence among new operators, encouraging faster adoption of modern press technologies.

Versatility Across Different Applications

From sheet metal punching to component prototyping, foot-operated electric presses can handle diverse tasks. Their adaptability allows workshops to manage different materials and tooling requirements without investing in multiple machines. Social media content highlighting multi-task functionality has made these presses particularly appealing to small and medium-sized businesses that value both efficiency and flexibility. The ability to quickly swap dies and adjust pressure makes them ideal for both large-scale production and small custom orders.

Reducing Operational Costs and Boosting Output

Efficiency improvements directly translate into cost savings. By enabling faster setups, reducing errors, and lowering labor fatigue, electric punch presses help businesses optimize workflow and reduce material waste. Many overseas buyers note that integrating foot-operated presses into existing lines increases productivity while maintaining consistent output quality. Reduced rework and less material scrap also contribute to a lower environmental footprint, a growing concern among modern manufacturers.

Digital Integration and the Future of Press Technology

The next generation of electric presses is expected to incorporate smart sensors, programmable settings, and integration with digital monitoring systems. Combining a Two-hand Button Electric Press with a foot-operated model allows factories to achieve both hands-on control and enhanced safety protocols. This synergy positions manufacturers to embrace automation trends while retaining operator engagement and precision. Overall, adopting these presses enables a balanced approach to efficiency, safety, and adaptability, meeting the evolving demands of modern industrial environments.

-

Feedback

English

English 中文简体

中文简体