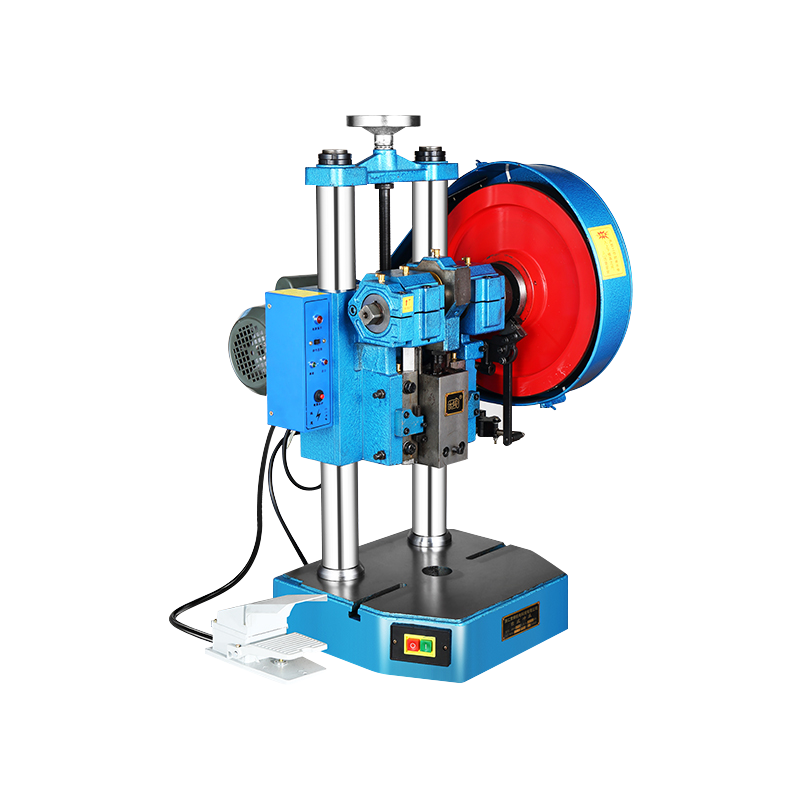

Why Are Modern Workshops Turning to Electric Punch Presses? Discover Efficiency in Action!

In today’s fast-evolving manufacturing environment, efficiency and safety are more critical than ever. Increasingly, companies worldwide are integrating the Foot Operated Electric Punch Press into their production lines, drawn by its blend of precision, speed, and hands-free operation. From sheet metal fabrication to small-scale assembly, workshops are realizing that these modern presses improve workflow while reducing operator strain. As businesses seek ways to optimize performance and remain competitive, foot-operated electric presses have become a focal point of industry conversations across LinkedIn, Reddit engineering groups, and technical webinars.

Hands-Free Operation Enhances Productivity

One of the primary reasons workshops favor foot-operated presses is the ability to control punching without using hands. This hands-free operation allows technicians to position materials more accurately, resulting in cleaner cuts and faster cycle times. It also reduces operator fatigue, especially in high-volume environments, making it ideal for repetitive production tasks. Professionals often highlight how minimizing hand involvement not only boosts speed but also improves overall safety by reducing accidental contact with moving components.

Precision and Consistency in Every Punch

Consistency is essential in manufacturing, and electric punch presses deliver repeatable, accurate results. Advanced control systems maintain uniform pressure, ensuring that every piece meets specifications. This precision is particularly valuable in industries where tolerances are tight, such as electronics, automotive components, and metal fabrication. Online technical forums show increasing interest from engineers evaluating presses for both small-scale prototypes and full-scale production lines.

Safety as a Key Selling Point

Workplace safety remains a central concern for manufacturers, and the foot-operated press addresses this by keeping operators’ hands clear of dangerous zones during punching. In addition, many presses feature adjustable guards, emergency stop functions, and overload protection. These built-in safeguards align with global safety standards and are frequently discussed on industry-specific platforms, reinforcing the importance of investing in well-designed machinery.

Versatility Across Industries

From automotive to HVAC and consumer electronics, manufacturers are finding applications for electric punch presses across diverse sectors. The ability to handle various metal thicknesses, toolings, and punch shapes allows companies to adapt quickly to different production needs. Social media communities and trade show discussions often showcase how one press can handle multiple tasks, offering small businesses and large factories alike a cost-effective solution for flexible production.

Reducing Operational Costs

Beyond efficiency and safety, the electric punch press can also help reduce operational costs. Faster cycle times and reduced errors mean less wasted material, fewer defective parts, and lower labor expenses. Companies report that investing in high-quality presses often results in measurable returns within the one few production cycles. These factors contribute to the growing interest among overseas buyers looking for long-term value rather than short-term savings.

Future Trends and Industry Adoption

As automation and smart manufacturing continue to expand, workshops are increasingly exploring presses that integrate with digital monitoring systems and programmable settings. The combination of hands-free operation, precise control, and versatility positions the Two-hand Button Electric Press as a natural complement to the foot-operated model, creating a robust, adaptable solution that meets the modern demands of production efficiency, safety, and reliability.

-

Feedback

English

English 中文简体

中文简体