Operators Combine Hand Press Punching Machines With Tapping Equipment To Streamline Workflow

In many small-scale manufacturing and workshop environments, efficiency often depends on how well individual tools and processes can be combined. One trend that continues to gain attention is the integration of the hand press punching machine with the semi-automatic tapping machine. This pairing helps streamline workflow and enhances productivity without requiring a major overhaul of existing equipment or production layouts.

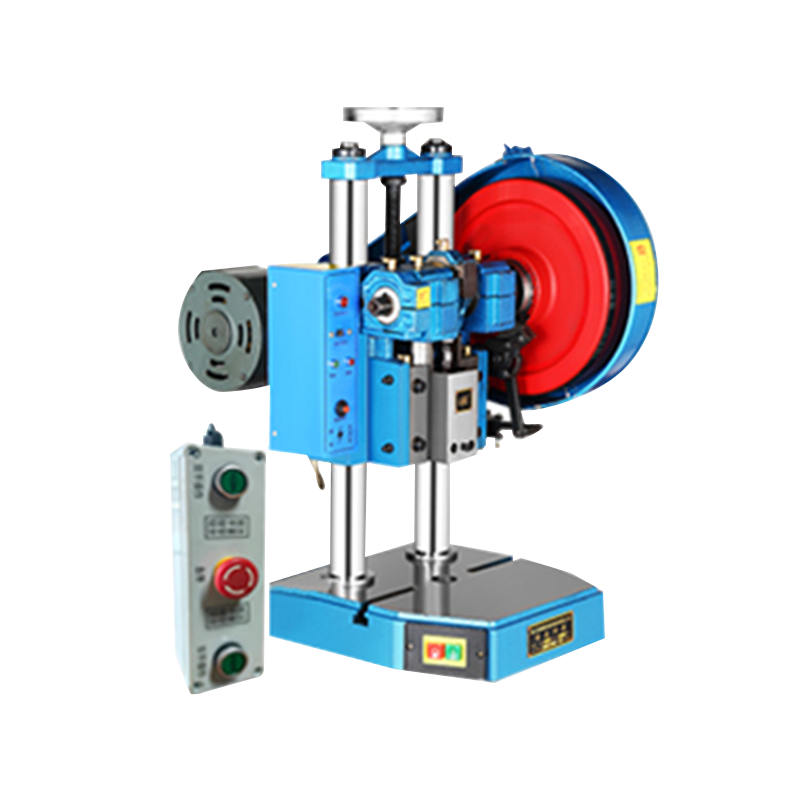

A hand press punching machine is typically used for simple punching tasks such as creating holes in metal sheets, plastic components, or other materials. It operates manually but offers precise control and requires small energy input. Despite its straightforward design, it remains a reliable fixture in fabrication lines where flexibility and simplicity are valued. When paired with a semi-automatic tapping machine, this basic tool becomes part of a more fluid process that reduces the time between operations.

The semi-automatic tapping machine is widely adopted for its ability to create threaded holes at consistent depths and pitches. Its design allows an operator to quickly secure parts, initiate tapping, and remove the finished product with limited interruption. In many workshop setups, operators one punch the material using the hand press punching machine and then immediately transition to threading the hole using the semi-automatic tapping machine. This sequence reduces handling time and supports more efficient task management, especially when batches of parts are being processed.

A key advantage of using both machines in tandem is that they complement each other without requiring complex synchronization. While the semi-automatic tapping machine adds mechanization to a precise part of the process, the hand press punching machine retains a manual aspect that offers adaptability in different material thicknesses or shapes. This dual-method approach is especially practical in operations where quick adjustments are needed, and automation is introduced selectively.

For operators, this method of combining equipment less unnecessary movement and enhances focus. Instead of walking between workstations, many workshops set up the semi-automatic tapping machine adjacent to the hand press punching machine, allowing seamless handoffs. This close arrangement fosters a more continuous workflow and helps reduce fatigue associated with repetitive motion and part transfer.

Another factor contributing to this integration is space efficiency. Many small or medium-sized production sites have limited floor area. By placing a hand press punching machine and a semi-automatic tapping machine within close proximity, operators can complete punching and threading operations within a compact workspace. This setup also simplifies training since both machines are relatively easy to operate and do not require high levels of technical adjustment.

In practice, operators often start the shift by setting up blank workpieces next to the hand press punching machine, where holes are one made. These pieces are then passed directly to the semi-automatic tapping machine, which completes the threading. This method allows for a rhythmic cycle that aligns with the flow of small-batch production or prototyping work. Importantly, this arrangement does not demand complex control systems, making it accessible for a variety of teams.

Integrating the hand press punching machine with a semi-automatic tapping machine presents a practical and effective way to streamline workshop workflows. By simplifying transitions between steps and maintaining consistent quality, this setup allows teams to keep production moving steadily. For many manufacturing environments, especially those focused on small runs or custom parts, this combination remains a useful and sustainable approach to enhancing daily operations.

-

Feedback

English

English 中文简体

中文简体