Demand Rises For Semi-Automatic Tapping Machines In Custom Metal Fabrication Lines

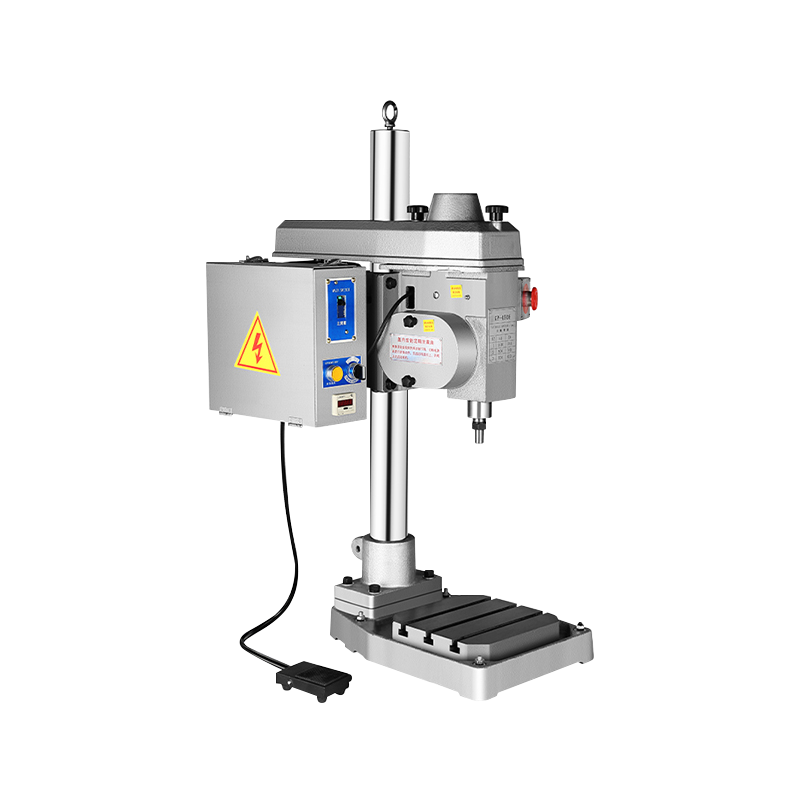

In recent years, the rise of custom metal fabrication has brought renewed attention to the efficiency and precision of various tools used in production. Among them, the Semi-automatic Tapping Machine has gained traction due to its ability to perform consistent threading operations across a wide range of parts. These machines are increasingly used in workshops looking to meet unique specifications while maintaining throughput in medium-scale environments.

Unlike manual tapping setups, a Semi-automatic Tapping Machine combines controlled mechanical motion with user input, offering a balance between automation and operator supervision. This arrangement proves valuable in custom jobs where full automation may not be economically justified. Manufacturers often seek a solution that fits within a flexible production setting without requiring large capital investments or lengthy setup times. The Semi-automatic Tapping Machine answers this need by streamlining tapping operations while still allowing for variation in part size and material.

In parallel, the hand press punching machine continues to serve as a dependable piece of equipment in the early stages of fabrication. For small-batch or prototype production, punching holes, slots, or indentations with a hand press punching machine allows for quick adjustments and small tooling changes. Its ease of operation and low maintenance requirements have preserved its relevance even as more automated equipment becomes common.

Interestingly, many small to medium-sized shops now use a combination of these two machines to enhance workflow efficiency. A typical sequence may begin with a hand press punching machine preparing the base material with initial shaping or perforations. This is followed by the use of a Semi-automatic Tapping Machine to apply threads to the pre-punched holes, creating a seamless transition between forming and finishing steps. The integration of these machines supports a modular production setup, allowing fabricators to adjust processes quickly in response to changing design demands.

It’s also worth noting that operators working with both the Semi-automatic Tapping Machine and the hand press punching machine appreciate the control and tactile feedback offered by these systems. While digital interfaces and software integration have their advantages, manual and semi-automatic tools still provide intuitive handling and immediate responsiveness, which is often preferred in custom fabrication tasks.

The adaptability of the Semi-automatic Tapping Machine makes it suitable for materials such as aluminum, mild steel, and various alloys used in brackets, casings, and structural supports. Similarly, the hand press punching machine remains a versatile tool for handling sheet metal or flat stock in various thicknesses. The two machines together contribute to building a flexible, step-by-step workflow that accommodates a wide range of part geometries and tolerances.

As metal fabrication continues to shift toward customized and low-to-medium volume production, equipment that supports responsive and adaptable operations is seeing increased demand. The Semi-automatic Tapping Machine fits naturally into this environment, often paired with manual devices like the hand press punching machine to complete key forming and finishing stages. This pairing is becoming a common sight on production floors where versatility and precision must coexist.

The integration of semi-automated tapping and manual punching reflects a broader trend in metalworking—an emphasis on adaptability, precision, and efficiency without relying entirely on full automation. Both the Semi-automatic Tapping Machine and the hand press punching machine continue to demonstrate their value in settings where flexibility and process control are central to operations.

-

Feedback

English

English 中文简体

中文简体