Hand Press Punching Machines Remain Valuable Tools In Low-Volume Production Settings

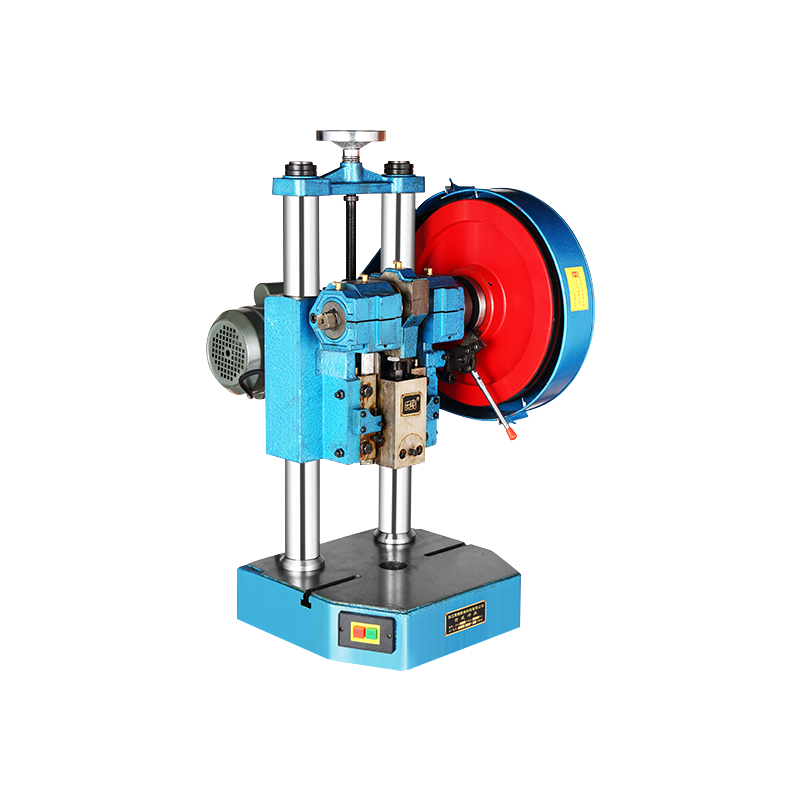

In many production environments where custom or small-batch manufacturing is the norm, the hand press punching machine continues to serve as a valuable piece of equipment. These machines are simple to operate, require small maintenance, and offer precise control over punching operations. For workshops dealing with light to moderate sheet metal tasks, especially where flexibility and quick changeovers are essential, the hand press punching machine remains relevant.

One of the key advantages lies in its suitability for low-volume production. Unlike high-speed automated machinery that is often optimized for mass manufacturing, the hand press punching machine allows operators to adjust settings quickly without complex reprogramming. This feature is particularly important when working with varied materials or dimensions, which are common in small-scale projects.

In many of these same workshops, another device that often complements the punching process is the Semi-automatic Tapping Machine. While punching machines take care of cutting or shaping, tapping machines are used to create threads in pre-drilled or punched holes. The Semi-automatic Tapping Machine offers consistent thread depth and alignment, making it a logical partner in workflows that require drilled holes to be tapped afterward.

The pairing of these two machines allows operators to build a streamlined, manual-to-semi-automated assembly line. After punching holes using a hand press punching machine, components can be moved to a Semi-automatic Tapping Machine station for further processing. This sequence provides a controlled method of producing accurately tapped and punched parts without the overhead cost of full automation.

Another advantage often cited by users is the portability and compact size of both the hand press punching machine and the Semi-automatic Tapping Machine. These machines can be moved, rearranged, or even transported to different job sites when necessary. This adaptability suits small enterprises and repair shops that do not have fixed layouts or high-volume requirements.

In terms of efficiency, a skilled operator using a hand press punching machine can achieve respectable output with small training. The tactile feedback and manual force application give users a strong sense of control, reducing the likelihood of material waste. When used in tandem with a Semi-automatic Tapping Machine, threading operations become faster and more uniform, especially in comparison to manual tapping methods.

Maintenance for these tools is also straightforward. The Semi-automatic Tapping Machine typically requires occasional lubrication, alignment checks, and replacement of worn tapping heads. Meanwhile, the hand press punching machine often continues to function with only basic upkeep such as die replacement and regular cleaning.

Today, as more manufacturers look for reliable ways to handle specialty or custom orders, the role of the hand press punching machine remains stable. It is not uncommon to see these machines in use alongside more modern equipment. Similarly, the Semi-automatic Tapping Machine finds its place in production where threading precision and speed are necessary but full automation is not justified.

Both the hand press punching machine and the Semi-automatic Tapping Machine continue to hold their ground in low-volume and flexible production settings. Their ability to adapt to varying work requirements and their relatively low maintenance needs make them suitable tools in environments where production variety and cost control matter.

-

Feedback

English

English 中文简体

中文简体