Small Workshops Increase Use Of Semi-Automatic Tapping Machines For Consistent Threading

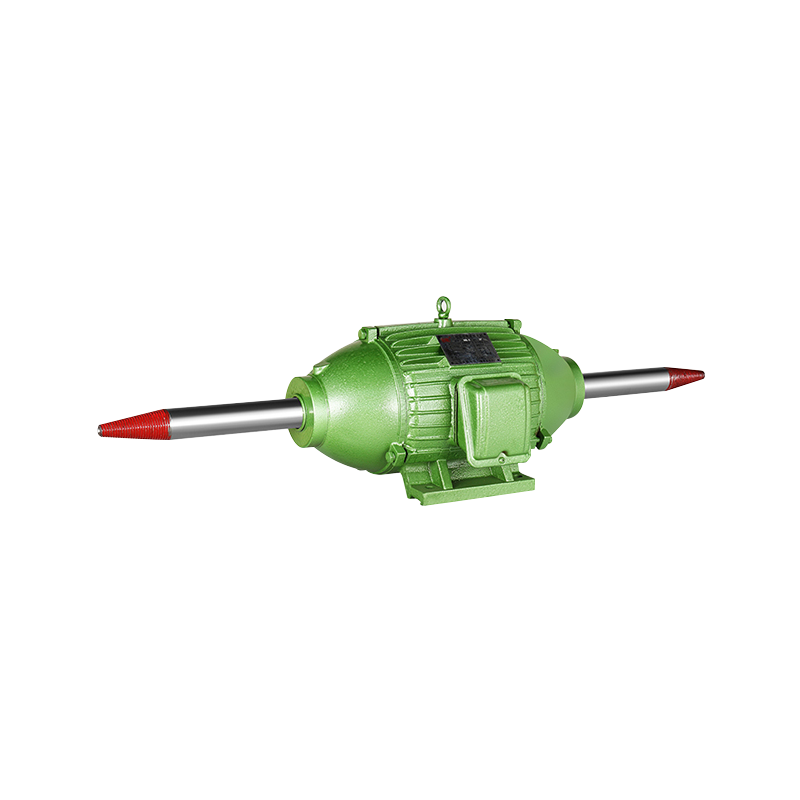

In recent years, many small workshops have been turning to equipment that offers a balance between manual control and automated support. Among such equipment, the Semi-automatic Tapping Machine has gained particular attention due to its ability to improve threading consistency without the complexity of fully automated systems. For operations that deal with moderate production volumes and custom parts, this type of machine brings precision and time-saving advantages.

The Semi-automatic Tapping Machine is particularly useful in scenarios where manual tapping would introduce variations due to operator fatigue or inconsistency. Small workshops often work on diverse materials and sizes, requiring tapping on both large and small batches. In these conditions, maintaining thread quality can be a challenge. These machines allow operators to maintain a steady rhythm of production while ensuring that each tapped hole maintains a uniform depth and pitch.

While tapping operations are becoming more efficient, punching tasks still require reliable solutions. Many shops still rely on the hand press punching machine for punching holes in sheet metal, plastic components, or other lightweight materials. The reason for its ongoing popularity lies in its simplicity and ease of use. Without requiring electricity or complex programming, the hand press punching machine provides manual control that many technicians find dependable for short-run jobs or prototyping.

In some workshops, a combination of both machines—the Semi-automatic Tapping Machine and the hand press punching machine—creates a versatile workflow. For example, punched parts from the hand press can be quickly transferred to the tapping machine, allowing for threading immediately after punching. This layout suits operations that need adaptability without committing to large-scale automation.

Workshop owners are also noticing improvements in turnaround time when integrating these two machines into their daily processes. The Semi-automatic Tapping Machine helps reduce rework by maintaining thread quality, while the hand press punching machine allows for quick changes in tooling and hole size. Together, they form a compact and efficient work cell that supports both flexibility and output control.

As production demands shift, especially for custom or lower-volume runs, machine operators value equipment that bridges manual precision with mechanical assistance. The Semi-automatic Tapping Machine plays a crucial role in this space, offering an approach that reduces error rates and less physical strain. Meanwhile, the hand press punching machine continues to find a place due to its tactile feedback and ease of maintenance.

With more small-scale operations looking to balance budget and performance, these machines are likely to remain part of daily workshop routines. Choosing to integrate both tools allows businesses to react quickly to job changes and material specifications. A Semi-automatic Tapping Machine doesn't require the same programming skills as CNC equipment, which makes it accessible to a broader range of workers. Similarly, the hand press punching machine doesn't demand high power inputs or complex setup, giving it an edge in space-constrained environments.

The steady adoption of the Semi-automatic Tapping Machine and the enduring use of the hand press punching machine reflect how workshops adapt tools to meet practical needs. Rather than replacing manual methods entirely, many are combining traditional equipment with semi-automated solutions to support steady output, reliable threading, and cost-effective punching. This balanced approach helps small workshops stay productive and maintain quality without overextending on capital equipment.

-

Feedback

English

English 中文简体

中文简体