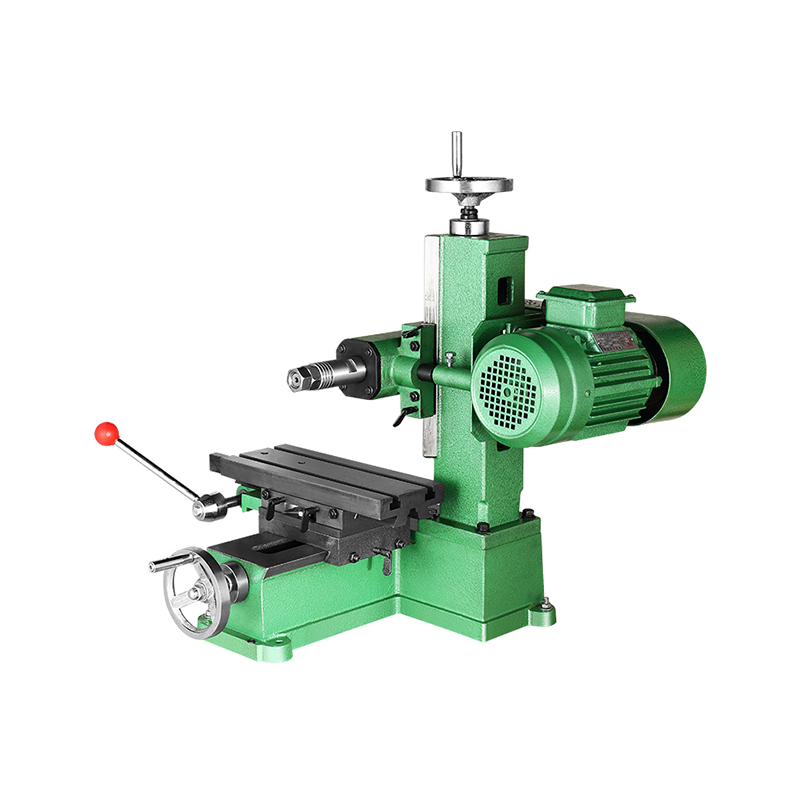

Why Is My Desktop Mini Milling and Grinding Machine Vibrating? Causes and Fixes

Vibrations during the operation of Desktop Mini Milling and Grinding Machines are a common occurrence. Although some vibration is expected in these processes, excessive or persistent vibrations can negatively impact the quality of your work, reduce precision, and potentially cause long-term damage to the equipment. This guide explores the main causes of vibrations in Desktop Mini Milling and Grinding Machines and provides effective solutions to reduce them.

A prevalent source of vibration in Desktop Mini Milling and Grinding Machines stems from components that are either loose or not correctly installed. The natural wear and tear from regular use can cause fasteners such as screws, nuts, and bolts to become loose, resulting in operational vibrations. Key areas to inspect include the machine bed, tool holder, and spindle.

Regularly inspect and tighten all screws, bolts, and nuts to maintain ideal performance and reduce vibrations. If any components are found to be loose, secure them using appropriate tools such as wrenches or screwdrivers. Additionally, conduct periodic disassemblies of the machine for thorough maintenance. During these inspections, look for signs of wear or damage that could be contributing to the vibrations.

The surface on which your Desktop Mini Milling and Grinding Machine sits plays a crucial role in minimizing vibrations. If the machine is placed on an uneven or unstable surface, vibrations can be amplified, affecting both the machine's performance and the quality of the work. This is especially noticeable during grinding or milling, where precision is key.

Ensure that your machine is placed on a solid, level surface. If you're working on a smaller bench or workspace, consider using anti-vibration mats or pads underneath the machine to absorb some of the vibrations. This can significantly reduce unwanted movements and improve overall stability during use.

The tool or grinding wheel used in your Desktop Mini Milling and Grinding Machine can also cause vibrations, especially if it's worn, out of balance, or improperly mounted. If the tool is not properly aligned or has uneven wear, it will create an imbalance that results in vibrations during operation.

Check the condition of your tools regularly. Replace or sharpen them if needed. Also, ensure that they are securely mounted in the machine. For grinding tasks, make sure the grinding wheel is balanced and aligned with the spindle. Some machines allow for adjustments to the tool holder or spindle to correct alignment issues.

Vibrations in a Desktop Mini Milling and Grinding Machine can also result from running the machine at an incorrect speed. Too high of a speed, especially with smaller tools or delicate materials, can cause instability. Similarly, running the machine too slowly can cause unnecessary strain on the motor, resulting in vibrations.

Refer to the user manual for recommended speed settings based on the material you are working with. For many tasks, it’s ideal to start with a moderate speed and adjust as necessary. Avoid pushing the machine too hard, especially when working with tougher materials that require more time and precision.

The material being processed can also play a role in vibrations. Harder materials or larger workpieces can cause the machine to vibrate more, especially if the workpiece is not secured correctly. A loose workpiece can cause shifts and imbalances during milling or grinding, resulting in vibrations.

Always ensure your workpiece is securely clamped or mounted in the machine. Use appropriate fixtures or vises to hold the material steady during operation. If you are working with a particularly hard material, consider reducing the feed rate or using a more appropriate tool for that specific material.

Lack of proper lubrication or infrequent maintenance can cause parts of the Desktop Mini Milling and Grinding Machine to work inefficiently, resulting in excessive vibrations. Dry or improperly lubricated moving parts may generate friction, which can cause the machine to vibrate more than usual. Additionally, the buildup of dust and debris can affect the internal components, increasing the likelihood of vibration.

Make it a habit to clean and lubricate your Desktop Mini Milling and Grinding Machine regularly. Refer to the user manual for recommended lubricants and cleaning procedures. Keep dust and debris away from moving parts, especially around the spindle and tool holders, to ensure smooth operation.

Vibrations in a Desktop Mini Milling and Grinding Machine are a common issue, but with the right knowledge and care, they can be reduced. By regularly checking for loose components, ensuring a stable work surface, maintaining tools, and using proper speeds, you can significantly reduce vibrations and improve the precision of your work.

-

Feedback

English

English 中文简体

中文简体