The Hidden Risk of Outdated Presses: How Two-hand Button Electric Presses Redefine User-Centric Safety!

For years, safety tools were designed mainly to meet regulations—not to truly protect the people using them. However, manufacturing trends in 2025 are shifting toward "human-centric safety," and the Two-hand Button Electric Press is at the forefront of this change. Workers are increasingly speaking up about how poorly designed equipment leads to fatigue and mistakes, making the ergonomic innovations of this tool a popular topic online.

Why Haptic Feedback Matters

One often overlooked safety feature is haptic feedback—the physical "click" that confirms the press has been activated. Older, low-quality presses usually lack this feature, and this absence can result in accidental misfires. The Two-hand Button Electric Press includes precise haptic controls, a detail that safety experts are praising on social media. This tactile response reduces mental stress because workers don’t have to wonder whether the tool is working correctly.

Ergonomics That Reduce Long-Term Strain

Repetitive motion injuries are a serious issue in manufacturing, and online communities are raising awareness about this problem. Two-hand Button Electric Presses come with adjustable buttons and lightweight designs, which help reduce strain on the wrists and shoulders during long shifts. Unlike heavy manual presses, these tools are designed to suit different body types, promoting a more inclusive and comfortable work environment.

How It Prevents "Safety Complacency"

Complacency is a major cause of workplace accidents, but the design of the Two-hand Button Electric Press helps keep workers focused. Features such as anti-repeat mechanisms and clear visual indicators—like LED lights—act as constant reminders to stay alert. Safety trainers on platforms like Instagram share videos showing how this tool helps prevent routine errors, pilot to fewer accidents compared to older equipment.

Enhanced Protection Through Dual-Hand Operation

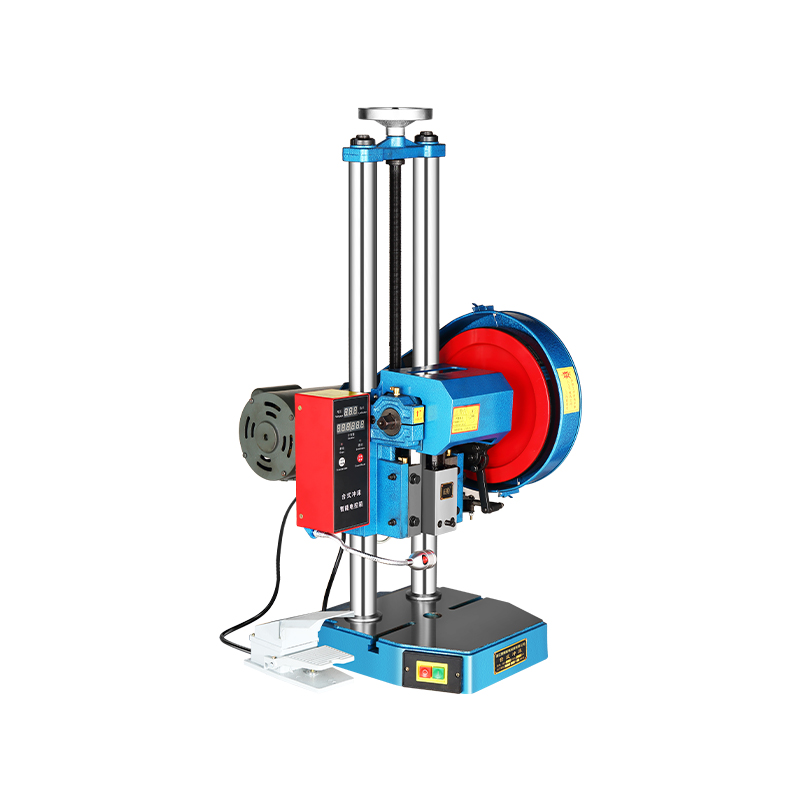

A key safety advantage of this press is its two-hand button design, which requires the operator to use both hands to activate the machine. This ensures that hands are kept away from dangerous moving parts during operation, significantly reducing the risk of injury. This design is especially useful in high-speed production environments where focus can fade over time.

Durability and Low Maintenance

Built with high-quality materials, the Two-hand Button Electric Press is designed to last longer than traditional presses. Its electric mechanism reduces wear and tear, meaning fewer breakdowns and less downtime. This reliability not only improves safety but also supports continuous workflow, helping projects stay on schedule.

Adapting to Various Work Scenarios

Whether used in automotive assembly, electronics manufacturing, or metalworking, this press offers flexibility across different tasks. Its adjustable settings allow it to handle various materials and thicknesses, making it a versatile addition to any workshop. This adaptability means companies don’t need multiple specialized machines, saving both cost and space.

The Two-hand Button Electric Press represents a significant step forward in industrial safety. By focusing on human factors such as ergonomics, feedback, and attention management, it addresses risks that older equipment ignores. As industries continue to prioritize worker well-being, tools like this will play an essential role in creating safer, more efficient workplaces. Investing in such equipment isn’t just about following rules—it’s about valuing people and performance.

-

Feedback

English

English 中文简体

中文简体