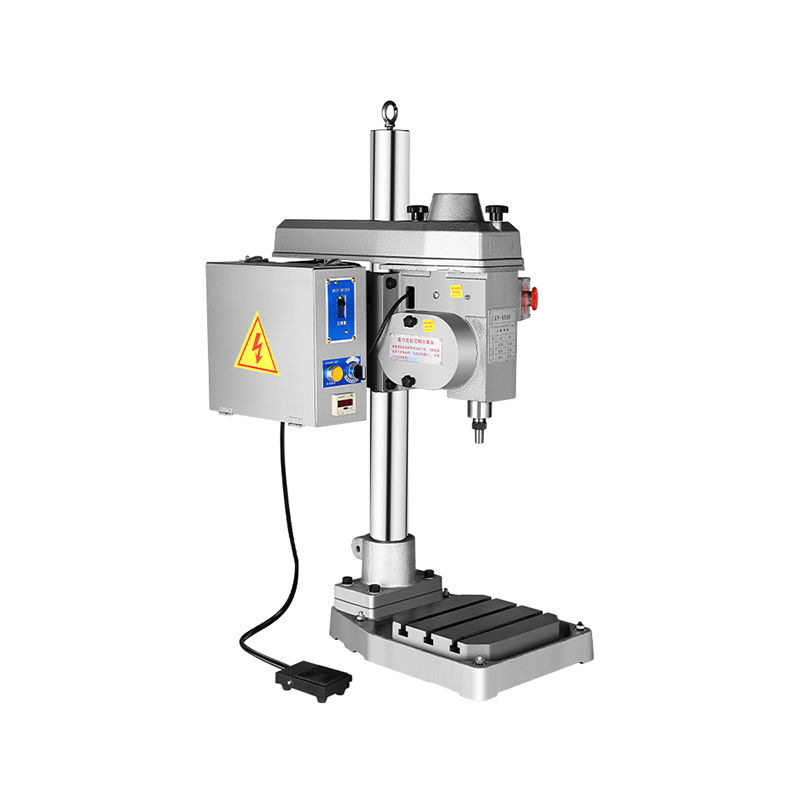

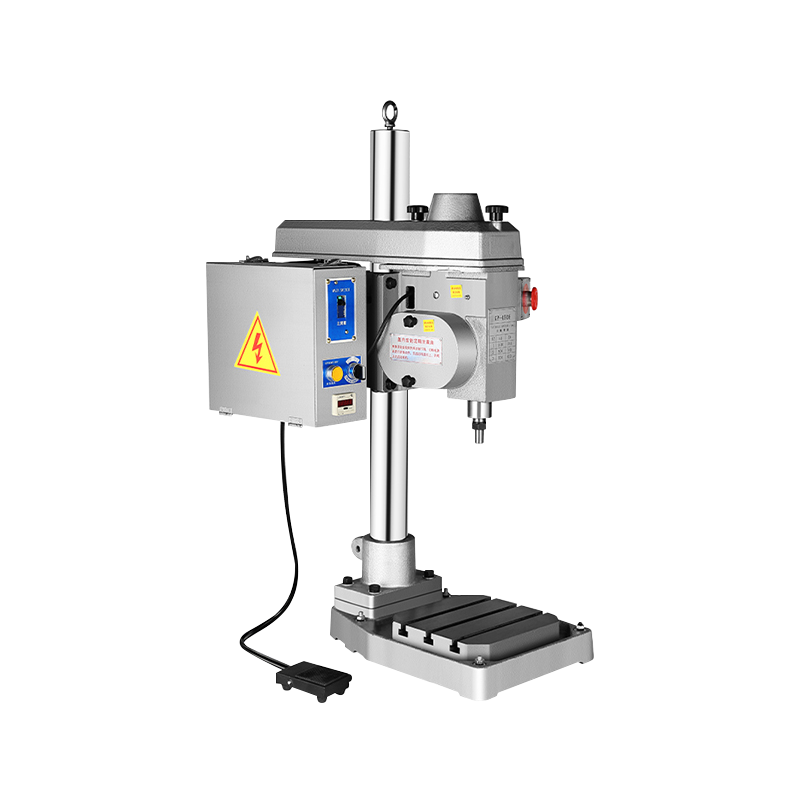

Gongpin Brand Small Power Head Desktop Semi-automatic Tapping Machine

-

Specifications

Model: GP-4508 Max Tapping Capacity (steel): Max. Tapping Frequency: 30 times/min Distance Spindle Axis to Column Surface: 185mm Max Distance Spindle Nose to Base: 350mm Spindle Travel: 45mm Spindle Speeds Range: 420, 760, 1340rpm Spindle Taper: B16 Dimension of Worktable Surface: 230 x 225mm Lead Screw: 0.4, 0.5, 0.7, 0.8, 1.0, 1.25mm Motor: 750W -

Feedback

Product Advantages

-

We possess a strong R&D team to develop and produce products according to the drawings or samples provided by customers.

We possess a strong R&D team to develop and produce products according to the drawings or samples provided by customers. -

We have our own testing lab and the advanced and complete inspection equipment, which can ensure the quality of the products.

We have our own testing lab and the advanced and complete inspection equipment, which can ensure the quality of the products. -

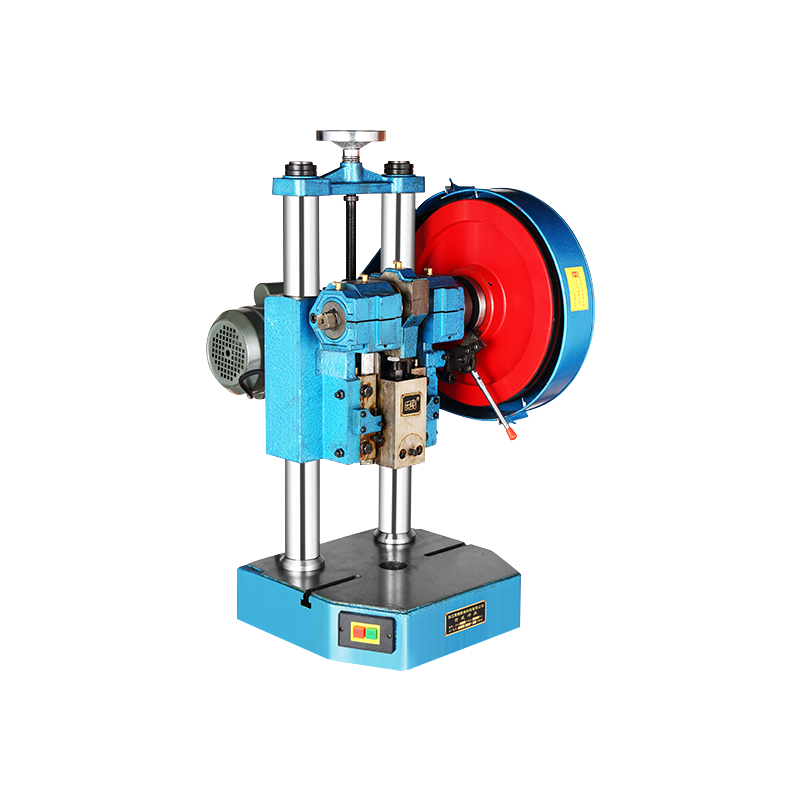

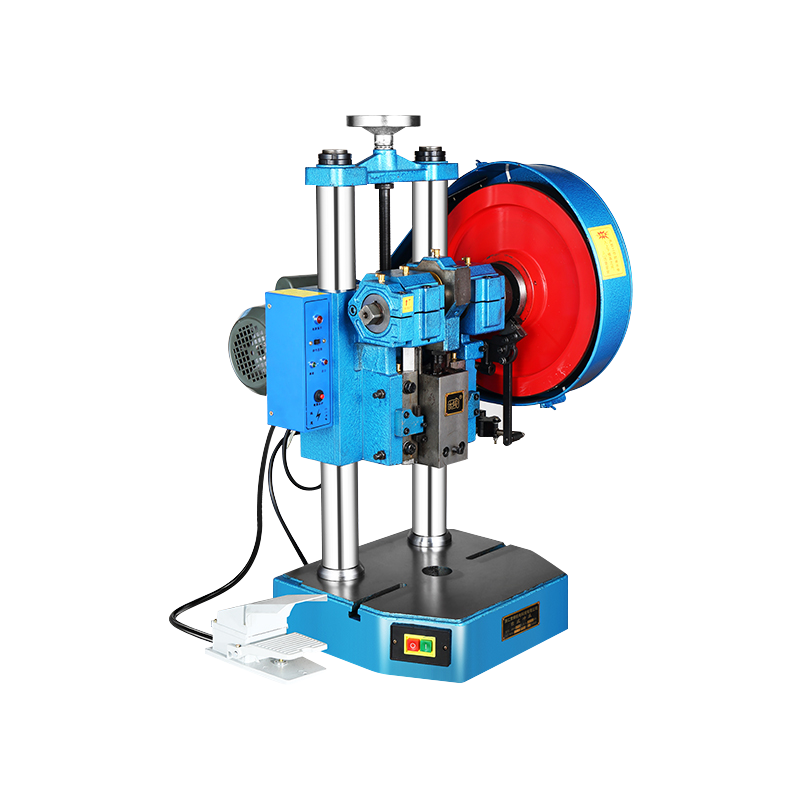

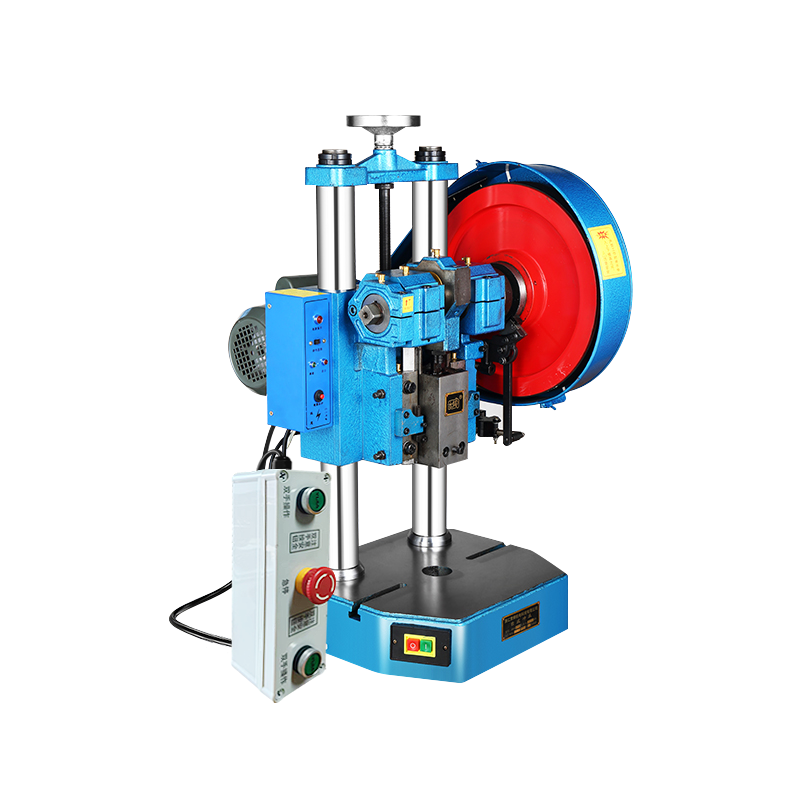

We have an extensive product line with multiple machines available and quoted on the same platform.

We have an extensive product line with multiple machines available and quoted on the same platform. -

We have 35 automation equipment, 15 production lines to meet the needs of customers with different purchase volumes.

We have 35 automation equipment, 15 production lines to meet the needs of customers with different purchase volumes.

Zhejiang Gongpin Electromechanical Technology Co., Ltd. is an enterprise integrating R&D, manufacturing, sales and services of various small and medium-sized motors and mechanical equipment. It has several engineers, a group of high-quality staff and modern high-tech inspection instruments.

Strong technical force. The company covers an area of 18,000 square meters and has a construction area of 12,000 square meters. It is located in the prosperous industrial and trade town Zeguo Shuicang Industrial Zone beside National Highway 104, close to the Ningbo-Taiwan Expressway, adjacent to Jiaojiang Wharf and high-speed rail station, and south of Huangyan Airport 5 kilometers, Wenzhou

The airport is 80km away, and sea, land and air transportation are extremely convenient. Our factory specializes in manufacturing Y, Y2, YD, YVF2, YL, YC, YS, JW, AO series single and three-phase motors, micro motors, ventilation motors, special special motors and polishing machines, desktop series punch machines, desktop milling and grinding machines, gears pitch automatic tapping machines and other mechanical equipment. We insist on developing based on technology, seeking market based on quality, continuous innovation and steady development.

Looking to the future, we adhere to the business philosophy of "quality for survival, integrity for mutual benefit and common development", and "advanced technology, continuous improvement" as our pursuit direction, and move forward bravely! We sincerely welcome new and old customers to visit us for guidance and create brilliance together!

-

In metalworking and fabrication industries, efficiency, precision, and operator safety are becoming critical priorities. Professionals across overseas forums and industrial social media are increasingly discuss...

READ MORE -

In industrial workshops around the world, efficiency, precision, and reliability have become essential for success. Many professionals have realized that traditional manual punching methods, while familiar, oft...

READ MORE -

In today’s competitive manufacturing environment, precision, speed, and reliability are more important than ever. Professionals worldwide are exploring solutions that reduce manual errors and improve output. Am...

READ MORE -

Across global manufacturing communities, a clear message is emerging: factory upgrades are no longer driven only by speed or scale. Instead, overseas buyers are actively discussing how smarter press solutions c...

READ MORE -

In recent overseas manufacturing discussions, precision control and workplace safety are no longer treated as optional upgrades—they are becoming baseline expectations. As factories adapt to stricter compliance...

READ MORE

English

English 中文简体

中文简体